Flexible touchscreen displays have been the stuff of legend, speculated by many, but executed by few. At least, not in a solution that really “wows”, and dare I say, matters. LG’s G Flex was lauded as the “world’s first curved, flexible smartphone,” when it was demoed at last year’s CES, but its flexible display was rendered inflexible by the rigid case that enclosed it. This may all change soon; a team of researchers from Germany’s Saarland University have developed a technique that could potentially allow anyone to print their own touchscreen display.

“So far, nothing like this has been possible,” says researcher Simon Olberding. “Displays were produced for the masses, never for one individual user.”

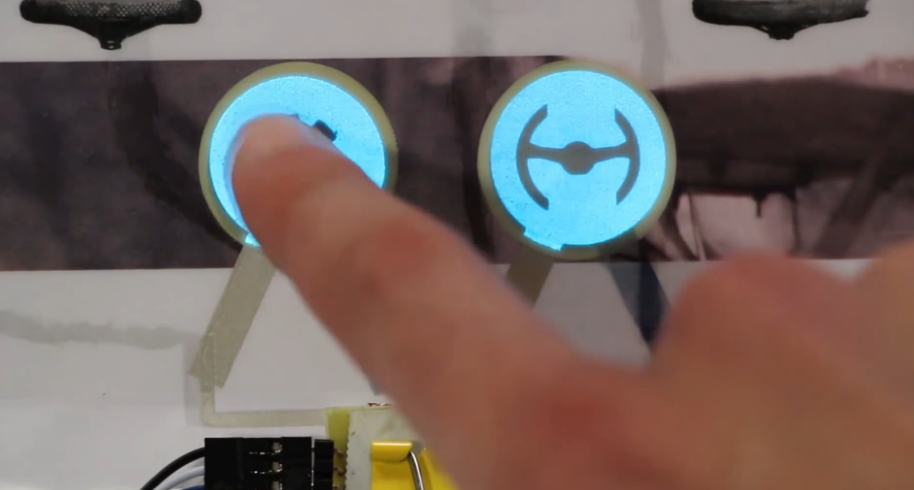

The technique — dubbed PrintScreen — relies on a standard inkjet printer loaded with a special conductive ink and a digital template of the desired size, selected from Microsoft Word, to print a DIY thin-film electroluminescence (TFEL) display. Of course, PrintScreen is a tad more complex than simply clicking print; it can take anywhere from several minutes to four hours to create a working custom display. Olberding claims the final products are worthwhile, resulting in “relatively high resolution displays,” that are one tenth of a millimeter thick. The average cost of covering an entire 8.5 by 11 inch sheet with the displays equates to roughly €20 (US$21.69).

The research paper points out that the PrintScreen method supports other multiple substrate materials, including office paper, transparent or nontransparent PET film, leather, wood, ceramics, marble, and steel. As a result, the technique can be used to print touch-sensitive displays as well, states Olberding. This opens up an entire realm of possibility, suggesting that homemade touchscreen may one day become embedded in a variety of household objects from furniture to appliances.

“And if we now combine our approach with 3D printing, we can print three-dimensional objects, which are able to display information and respond to touch as well,” says lead researcher Jürgen Steimle.

With the onset of PrintScreen and other such technology, rapid prototyping will reach a whole new level, allowing the creation of design iteration upon design iteration within a very short period of time. Couple this facet with 3D printing and the DIY makerverse will reach entirely new levels of ingenuity.

Advertisement

Learn more about Electronic Products Magazine