GRANT MASON,

Director of Sales for SCHOTT Gemtron,

www.schottgemtron.com

Smartphone screens, though measured in inches, continue to extend their reach. Designers strive to replicate their form in our homes, cars, hospitals, and businesses, and not just because they’re pretty to look at. No, the power of the screen lies in its functionality and operator guidance.

The knobs and buttons that once filled our electric devices at home or terminal dashboards have been replaced with tablet-sized smooth panels that control the radio, air conditioning, and plenty more.

It’s safe to say that the smartphones that live in our pockets and purses have changed the way we interact with the world. Engineers are now tapping into the influence of those intuitive taps, swipes, and presses, and applying them everywhere else.

The home is no exception. One space drawing the eye of designers is the kitchen, where touch switches are replacing knobs and buttons on stoves, refrigerators, and coffee makers. By taking advantage of our instinctual understanding of touch controls, designers are expanding possibilities of both form and function. And the most important technology involved in this transformation lies on the surface: the glass that fronts every screen and switch (see Fig. 1 ).

Fig. 1: Touch panels are giving appliances new layers of convenience — they’re simple to understand, easy to clean, and have long working lives.

Functionality meets style

Technology defines the kitchens and appliances of each generation. Decades ago, kitchens were functional spaces and the icebox was the height of technological advancement. The 21st century kitchen is now a cocktail of style and function, and even refrigerators have an integrated WLAN capable of communicating with other smart home applications and tablets.

Touch switches and panels stand to define the next generation of appliances. In its latest line of built-in ovens, steamers, and coffee makers, appliance manufacturer Miele, for example, uses small dimples on the glass control panel to give tactile feedback and signal the location of the on/off switch (see Fig. 2 ).

Fig. 2: Small dimples, or sliders, in the glass give tactile feedback and signal, for instance, the location of the on/off switch.

Touch switches are often engineered with haptic, acoustic, or visible responses. This feedback is both a design choice and a functional trait. While a traditional switch or knob is clearly in the on or off position, touch controls are more ambiguous, and must be engineered so cooks know for sure that they set the coffee pot to brew or turned off the stove after a meal is prepared.

Operation is the heart of the appliance, which is the reason why more manufacturers are building these easy-to-understand controls into their appliances. The tech-savvy consumer easily grasps these concepts, and intuitive touch switches are important in the acceptance of these appliances by consumers.

Coordination of operator guidance among a line of manufacturer’s products — called family design — is helping smart controls work their way into even more appliances. Now, a stove’s control panel will look much like that of its extractor hood, the microwave, and the coffee maker. The move toward family design in the modern kitchen is leading to more aesthetically pleasing controls in every appliance.

Pumping up power and appearance through touch screens

Appliance manufacturers have numerous style options to choose from when considering a family design. SCHOTT Gemtron’s glass panels can be processed for a flush-fit installation, and touch switches and screens can be printed in enamel or organic colors, and surface finishes — such as a metallic look, silky appearance, or a mirror effect — are possible. Haptic surfaces can also be differentiated through other surface effects. The controls can also be designed with semitransparent colors for integration of bright lighting effects. These glass panels can be customized for glass sheets larger than 220 mm, measured on a diagonal, and between 3 and 10 mm in thickness.

Glass not only looks very sleek, but also has great technical properties that make it superior to plastics for touch-sensing applications. Glass offers a dielectric constant between 5 and 7, which is better than plastic’s dielectric constant of between 3 and 4. The dielectric constant (ε) indicates how easily a material can become polarized by imposition of an electric field on an insulator. This is a necessary property for creating touchscreens and switches, and glass’s higher constant produces better results.

Dead fronting of backlight symbols and seven-segment displays can also be achieved. Dead fronting maintains one homogeneous surface appearance when off, and controls only become visible when an appliance is turned on — it keeps design front and center until function comes into play. Special 3D effects, including mirror coating on the front, can be combined with rearside printing.

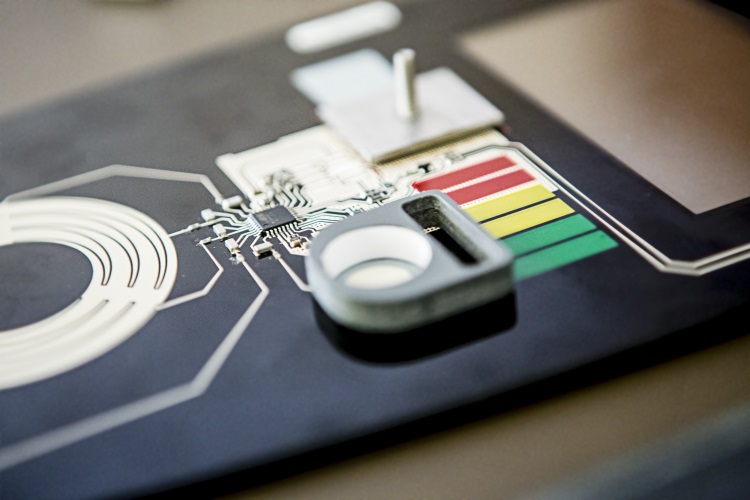

Finally, printed circuits and sensor areas for capacitive switch buttons can be designed for easy connections to electronic components. In addition, specific areas on the glass can be colored for infrared sensors with a wavelength range from 860 to 920 nm for both touch and touchless switches (see Fig. 3 ).

Fig. 3: Printed circuits and sensor areas for capacitive switch buttons can be designed for easy connections to electronic components.

These touch controls are for more than just appearance, however. Smooth control panels with touch switches are easy to clean, and glass’s hygienic smooth surface prevents large buildups of dirt and bacteria.

Mechanical shock resistance and reliability are other considerations. Because these panels have no joints or openings, the electronics behind the glass are protected from water penetration, thus preventing electronic failures. In the short term, electronics are protected behind the glass up to a temperature of 90°C, or 195°F; additionally, glass can withstand temperatures of up to 70°C, or 158°F, for long periods of time. The panels are also long-lasting and will not show visible signs of aging.

The return of the power of touch

Smartphones and tablets have once again made our fingers our greatest tools, and because 21st century design relies on design and simplicity, engineers are expanding our use of simple touch switches into home appliances and cars, as well as into commercial and medical applications.

Touch panels are giving appliances new layers of convenience — they’re simple to understand, clean easily, and have long working lives — while offering users the same certainty as knobs and buttons. These touch switches on control panels are both intuitive and attractive, and their inclusion in home appliances, as well as in cars and in industrial settings, is leading to easy interaction between appliance and user.

Advertisement