There are a number of thermoelectric (or thermal-electric) devices readily available for your designs. They fall into two categories. First, there are cooling devices; often used for fiber optic modules or stabilized oscillators. These use the Peltier effect to cool things via energy being put into the unit. For this article we here are interested in the opposite – modules that make use of the Seebeck effect, where electricity is generated across two plates due to their temperature differences. These devices have great potential for energy savings and for powering portable wireless IoT devices.

What is needed for this technology to be effective is waste heat – available in many industrial plants, automobiles, and power generation plants – and in smaller amounts in many every-day items, including the human body. In a typical automobile over 65% of the fuel’s energy content escapes in the form of waste heat. The most concentrated portion exits via the exhaust system, where temperatures can reach 500-600°C. Thermoelectric technology can convert the wasted thermal energy into useful electrical energy. This recovered energy can be used to minimize electrical loads by partially replacing the vehicle’s alternator, making a 5% boost in MPG feasible.

Low temperature and low temperature differential TEG devices, such as those for use on the human body, are possible but difficult. There have been demonstrations of thermoelectric micro-devices capable of providing 15 μW/cm3 from 10°C temperature gradients.

On the high power side, small thermoelectric generator (TEG) systems can be made. For example a 300 watt TEG assembly can fit into about a twentieth of the space required for an equivalent solar array. And, its output is 24 hours per day, as long as there is a heat source and a cold removal side. For best efficiency, using the present state-of-the-art semiconductor materials, it is advisable to have a temperature of 150 to 250°C (302-482°F) hot side, with a delta temperature (DT) of at least 100°C. Some materials work at lower temperatures. Presently, Bi2Te3 is probably the most efficient at room temperature.

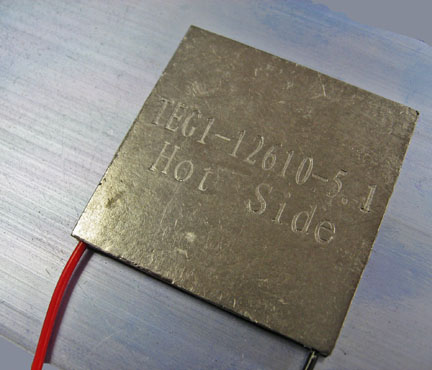

Tecteg Manufacturing (http://thermoelectric-generator.com) of Ontario, Canada has a number of thermoelectric generator modules available. For example, the 1.58 inch square TEG1-12610-5.1 has a hot side temperature of 50 to 300°C. It has a matched load output power of 5.1 W with an output voltage of 3.9 V at a TH of 300°C and a cold side temperature (TC ) of 30°C. The unit costs $30 ea/100.

The Tecteg TEG1-12610-5.1 thermoelectric generator module.

Materials such as PbTe (lead and tellurium), and CMO (Calcium Manganese hot side with Bismuth Tellurium cold side) have been used with temperatures of 350 to 600° C (702-1112°F). Both materials have had their characteristics and performance well documented and have been used extensively. Tecteg MFR has recently started offering PbTe as a hybrid thermoelectric module combining BiTe P-type and PbTe N-Type material. PbTe properties are better suited to temperatures above 300°C so the combination works well in the 300°C to 360°C range. They also offer CMO’s which work at very high temperatures 500°C to 800°C. Tecteg offers four classes of thermoelectric modules:

-Bi2Te3 (Bismuth Tellurium) Series 1. Up To 320°C

-PbTe-BiTe (Lead Tellurium/Bismuth Tellurium) HYBRID SERIES 1 PB. Up to 360°C

-Calcium Manganese Hot side with Bismuth Tellurium cold side CMO CASCADE. Up to 600°C

-Calcium Manganese Oxide CMO. Up to 800°C

Their low temperature modules (TEG2) are high current devices with contacts that are soldered using AgTn on both sides. Although the solder has a 240°C melting point, it begins to degrade at about 190-200°C and they recommend the hot side stay below 190°C.

For all TEGs, two critical factors dictate power output:

The amount of heat flux that can successfully move through the module.

The temperature of the hot side less the temperature of the cold side – delta temperature (DT).

Great effort must be placed on the heat input design, and especially the heat removal design (cold side). The better the TEG Generator construction is at moving heat from the hot side to the cold side and dissipating that heat as it moves thru the module array the more power will be generated. The best efficiency that can be achieved with the standard BiTe material is approximately 6%. But once the material is constructed into a module, efficiency drops to 3 to 4% because of thermal and electrical impedance. No other standard semiconductor material can perform as well as BiTe as far as efficiency is concerned.

Tecteg provides an interesting example design case:

You want to produce a 100 watt thermoelectric generator and this is based on a DT of 100°C.

Therefore:

1. You need at least 2000 watts of heat on the hot side given a 5% efficiency conversion to produce 100 watts of power.

2. To produce 100 watts you are required to dissipate 1900 watts of heat on the cold side continuously as only 100 watts is being converted to power.

How critical is DT? The same 100 watt TEG above will produce:

• 200 watts: If DT is increased to 150°C

• 350 watts: If DT is increased again to 200°C

But you must have the mechanical provisions to support the heat transfer. TEGs expand a lot with temperature and repeated heating and cooling can affect their lifetime dramatically. Different devices have different mounting specifications that must be paid attention to.

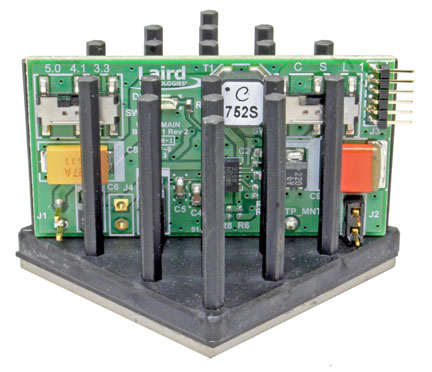

Laird Technologies (www.lairdtech.com) designs and manufactures TEG modules with three types of embedded thin-film designs. Each product in the series offers a unique output power based on footprint availability. The power generating product portfolio also includes the Thermobility Series wireless power generators. In these products, standard heat exchangers are provided to absorb and dissipate heat and output power can be regulated to a specific DC voltage set point. Options are available to store energy harvested from heat into a battery or integrate a sensor with communication via wireless M2M.

The 1.55 x 1.37 x 1.11 inch WPG-1 module from Laird outputs DC power and is suitable for powering wireless sensors and sensor networks. It can produce up to 1.5 mW and can handle a wide range of load resistances. It’s ultra-low voltage step-up converter provides usable output power at low temperature differentials,

The Laird WPG-1 is a self-contained thin film thermoelectric power generator.

Marlow industries (www.marlow.com) of Dallas Texas makes a number of thermoelectric generators. The 1.58 inch square TG12-6 is a good example. This 0.15 inch thick unit will provide about 3.2 W at 3.7 V when the cold side is kept at 50°C and the hot side is at 170°C. Recommended compression mounting pressure is 200 psi with thermal grease or flexible graphite pads. This device can be used at up to 230°C.

The Marlow EHA-L37L37-R01-L1 is a module that attaches to a pipe and has a DT startup of only 1°C and a power out of 0.8 mW at only 10°C DT. It costs $195 in single qty and includes a DC-DC converter in its 2.13 x 1.50 x 1.35 inch outline.

Advertisement

Learn more about Electronic Products Magazine