If there’s one thing to be learned from the internet, it’s that cats and 3D printers never get old. Almost every crowd funded 3D-printer campaign has ended in “great success,” and Peachy Printer is no different. In fact, the $100 printer and scanner amalgamation has raised over 1,000% of its total campaign goal in just half the campaign length. Peachy Printer aims to start a revolution in household gadgetry by lowering the entry cost and skill barrier of 3D printing, to initiate wide-scale adoption.

Affordability should not to be mistaken for rudimentary. Peachy Printer is a very capable printer, forgoing print-size in favor of print-quality. While it theoretically cannot print anything the size of a canoe, the team is willing to try to print and build one for any person philanthropic enough to pledge six grand for the campaign.

Lasers and audio files Shape the X and Y axis

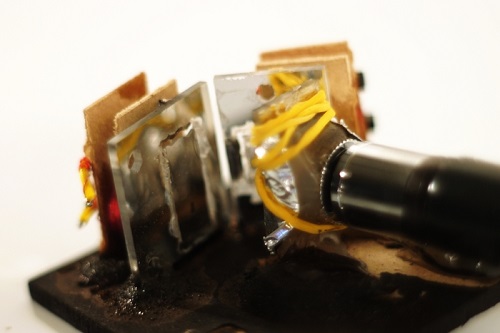

Peachy Printer is a photolithograph printer, meaning it employs a controlled light beam to cure sensitive resin in rigid objects. A laser moving along the X and Y axis fashions the shape while a drip system simultaneously allocates the necessary resin for the required height.

As in the case with all 3D printing, the designated shape must initially be produced using 3D modeling software. But instead of transferring these instructions from the computer to the printer using USB, Peachy Printer receives its instructions through the computer’s headphone jack.

Mirror direct the laser beam when cutting the X and Y axes

Once a schematic is completed, the proprietary blending software converts the CAD file into a transmittable audio waveform. The waveform then drives a pair of electromagnetic mirrors responsible for reflecting and controlling the path of the laser beam to formulating the X and Y axis of shape. Mirror movement rates depend directly on the volume of the audio waveform; the higher the volume, the higher the voltage, and therefore, the higher the movement.

Salt water for the Z

Printing the Z-axis of the designated shape is a matter of Chinese water torture. In other words, salt water is steadily dripped down a feed from a container located at the top of the printer. As the drops make their way down, they pass through two contact points creating an electrical connection that is picked up by your computer’s microphone jack. The drops continue falling until they’ve reach the bottom of container, causing the resin floating atop to rise. Next, the proprietary software listens to the microphone level to determine the resultant level of the resin with each drop. The software then transmits the layer correspond with the present Z-axis level of the resin; this process is repeated until the printing is completed.

What about the scanner?

Peachy Printer’s 3D scanning capabilities are rooted in the pairing of advanced software and external camera. In other words, owning a camera is a requirement for taking advantage of this feature; however, any type of camera will suffice: video camera, DSLR, point-and-shoot, or even webcam.

Scans are performed when a back and forth laser pattern is broadcasted from the Peachy Printer to illuminate the profile of the object being scanned and simulate a line laser. The object is then rotated in full 360 degrees while each frame is captured using the external camera. Once the scan is completed, the software, written in the open-source Blender modeling software, examines each pixel in every frame to look for the point where the laser is hitting the object. The distance between the pixels from the object’s rotational center and the laser are calculated and transformed into a 3D mesh. A future software update is in the works to allow the creation of texture map directly from footage.

Visit Peachy Printer’s Kickstarter page for the in-depth specs.

Advertisement

Learn more about Electronic Products Magazine