By Jean-Jacques DeLisle, contributing writer

A team of South Korean researchers from Yonsei University and Chung-Ang University have announced a breakthrough in organic light-emitting diode (OLED) technology and the creation of flexible OLED screens. This development could have wide-ranging applications across many tech industries. According to the recently published paper, the researchers have overcome many of the barriers that previously prevented flexible OLED screens in the past. The researchers have proposed a new architecture for OLEDs that greatly increases charge mobility and flexibility.

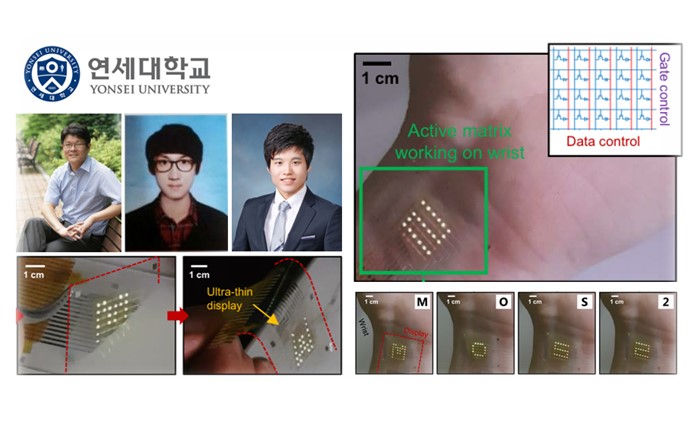

Image source: Yonsei University.

The new OLED display works by using molybdenum disulfide (MoS2 ), a material that has been extensively researched and classified as a semiconductor but, until now, has never been applied to OLED technology. The problem with using MoS2 in OLED screens is caused by its large-scale contact resistance. This contact resistance causes an electrical resistance in the areas where the MoS2 contacts other metals, causing a loss of energy and efficiency. It also makes the material lose much of its efficiency when bent or folded due to Coulomb scattering and trap charges at the interface between the gate dielectric and MoS2 , thus lowering charge mobility to under 1 cm2 V−1 s−1 on par with that of a-H Si, which makes its use as a flexible screen nearly impossible.

To overcome this obstacle, researchers have rearranged the architecture of the OLED completely, sandwiching a microscopically thin layer of MoS2 between two thin sheets of high-k dielectric aluminum oxide (Al2 O3 ). This new modified switching device architecture is proposed for efficiently exploiting the high-k dielectric Al2 O3 layer, which, when integrated into an active matrix, can drive the ultra-thin OLED display even in dynamic folding states. According to the researchers heading the project, the high-k Al2 O3 layer reduces the contact resistance at the metal/MoS2 interface, creating an innovative design that facilitates considerable n-type doping of the MoS2 layer, owing to its oxygen-deficient surface. This development on previous modules allows for the reduction of the scattering charge impurities. Additionally, the lower layer of Al2 O3 reduces surface roughness, a feature that can further improve the performance of devices as it effectively decreases the interface-trapped charge density.

What this all amounts to is a flexible, efficient, LED screen that can be folded up and unfolded, over and over again, without losing efficiency or breaking. So far, these South Korean researchers have already created a 6 x 6 OLED display using this technology, and it is designed to be flexible and attached to the wrist as a display for wearable technology. Possible future applications with this creative invention are endless, and we can expect to see this technology making its way into cellphones with flexible screens that will never crack or break. Televisions could wrap around corners or contour to odd surfaces with ease. OLED displays are already all around us, and with the flexibility offered by this new breakthrough, we can expect to see them in even more places in the years to come.

Advertisement

Learn more about Electronic Products Magazine