By Majeed Ahmad, contributing editor

The USB Type-C standard — a set of rules to make smarter USB cables, connectors, and plugs — continues to evolve while expanding the range of applications it can serve.

The one-piece solution for the data and power transmission without the need for a separate power adapter is quickly becoming popular in portable devices, datacenters, automotive diagnostic and infotainment systems, medical electronics, and outdoor LED displays.

At the same time, however, poorly designed USB Type-C cables, connectors, and other accessories can cause permanent damage to the hardware they are serving. So it’s imperative that Type-C cables — constructed with Type-C connectors on each end — meet the stringent quality standards.

Image: L-com.

Here is a quick review of three key design parameters that engineers need to take into account while making a decision about Type-C cables and accessories.

Power delivery

The “Benson Leung saga” has been extensively covered in the trade media. Leung, a Google engineer, ended up destroying his $800 Chromebook Pixel laptop because of the wrong resistor that miswired the USB Type-C cable.

It’s critical that the USB Type-C cable and connector send and receive the right amount of power, and that mandates the right components. A 56 kilo-ohm resistor and a system for leveling power will ensure that the cable draws only as much energy as the host device can provide.

Multifunction signaling transport

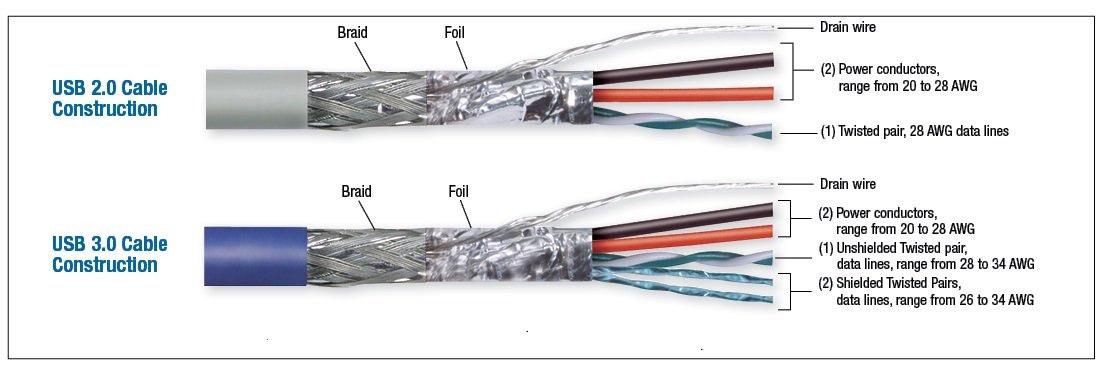

The USB Type-C standard also mandates that the cable is using precise wire sizes and that the connector is properly constructed. That, along with appropriate signal integrity and protection against RF and electromagnetic interference, allows multifunction signaling to work efficiently.

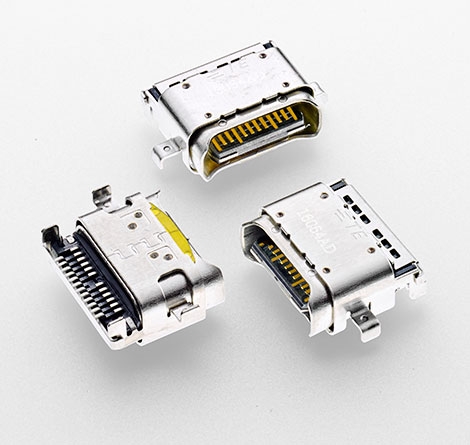

Take, for instance, TE Connectivity, a supplier of USB Type-C connector solutions. The company claims to offer a shielded design on the back of the receptacle shell to help eliminate unwanted electromagnetic interference (EMI) leakage.

Image: TE Connectivity.

Rugged construction

TE Connectivity also offers enhanced retention features and splash-proof options to ensure that USB Type-C connectors can operate in rugged industrial environments. That demands enhanced environmental sealing and mechanical strength.

For starters, the IEC-60529-IP67 specification ensures that the connection is sealed against dust ingress and is protected against high-pressure water jets. It also supports immersion in water for limited periods of time.

Next, the rugged construction of USB Type-C connectors can be accomplished with upgraded materials; for example, gold- and nickel-plated contacts for resistance against corrosion. The design features, such as a conductive silicone rubber gasket and threaded panel connection points, also allow connectors to operate in extreme environments.

The USB Type-C connectors also feature through-hole mounting to facilitate a mechanically robust PCB connection.

Advertisement