Industrial wireless networks are becoming very popular due to proven wireless technology, especially 802.15.4, which can cost effectively handle a wide range of sensing, control and management functions. The move from wired to wireless networks in industrial, manufacturing and warehousing applications is to reduce costs, improve uptime, save energy, and improve workplace safety.

Installation costs are cut by eliminating many wiring expenses and cable routing problems, while placing fewer restrictions on the location and placement of equipment. And wireless can reduce related costs for items like conduits and connectors. Another important factor is the speed of installation, particularly for factory floors that need to reconfigure their manufacturing and assembly lines quickly and efficiently. In wireless implementations, plant managers simply move the assembly machines to new locations and turn on the wireless network, eliminating the need to re-route cables or deal with new data cables.

Wireless to control and manage energy usage

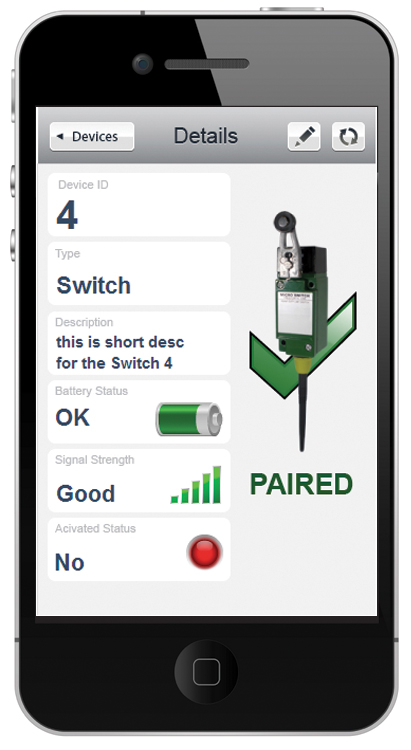

Large manufacturing plants, especially in the automotive industry, often have numerous large doors that if left open when not in use, can result in a waste of energy in heating and air conditioning. A wireless switch or position sensor on a door that communicates to a local server and then to the web enables easy monitoring of the open/close status of these doors using an app for the smartphone or other web-connected device (see Fig. 1 ).

Fig. 1: Wireless networks connected to the web can be monitored via a smartphone.

Wireless for industrial safety

Most industrial plants and facilities use a combination of safety showers and eye washes for chemical exposure hazards. Having a notification system that informs plant management or EMS personnel that an emergency has occurred, is a rising requirement within these plants and is being reviewed by governing bodies as a pending regulation.

These showers and eye baths can be located indoors or out, often in locations where it would be cost prohibitive to run a data cable. Wireless also allows these safety showers and alarm switches to be easily moved and repositioned.

Many current safety showers use an in-line flow switch that activates automatically. These are often difficult to maintain and are subject to failure and costly to replace. It is simple and cost effective to use a wireless system to replace them (see Fig. 2 ). Most users prefer to install the switch so that an alarm is sent automatically upon actuation. In other cases, a simple manual wireless push button switch can send a true alarm to plant management.

Fig. 2: Honeywell’s battery-operated Wireless Operator Interface (WOI) can be used for a safety shower or eye wash basin alert.

Industrial wireless for airport security

Airport hangars are often located a distance away from their associated offices or security checkpoints. The challenge is to monitor the status of these doors, especially the small cutout doors that are used for personnel access when the main door is closed (see Fig. 3 ). If the large hangar door rolls up while the pocket door is open, it can result in expensive damage. And with the need for increased security awareness, being able to monitor and track access to aircraft is critical.

Fig. 3: Switches mounted on the small hangar access door provide security.

In addition to solving the problem of installing and maintaining long cable runs underneath the pavement, the hangar doors cause extensive moving and flexing of cables that often results in breakage. Using battery-powered wireless sensors, there is no need for either data or power cables.

Additional security is provided by the network’s ongoing self-reporting – ensuring that the connections are secure and that battery power is adequate.

Wireless helps prevent truck stop thieves

Wireless networks are being installed in truck stops across the nation to help monitor remote diesel and gas pumps in order to prevent theft. Some truck drivers and operators have learned how to open the pumps and then set them so that they can pump fuel into their vehicles without it registering on the station’s controllers or cash registers. By attaching wireless sensors on the pumps that send an alarm to the office, the station operators know when a pump has been opened and can take corrective action.

Installing a wireless 802.15.4 network is much less expensive than a hard-wired solution and only takes a few hours to set up and install

Advertisement

Learn more about Honeywell Sensing and Productivity Solutions