Texas Instruments Inc. (TI) has launched its first intelligent power module (IPM) and the industry’s first 650-V three-phase gallium nitride (GaN) IPM for 250-W motor drive applications. The DRV7308 GaN IPM addresses the key challenges—efficiency, size and cost—that engineers typically face when designing major home appliances and heating, ventilation and air-conditioning (HVAC) systems. A newly released Power Electronics Survey, conducted by Power Electronics News, finds that the most critical objective in power electronics component selection is efficiency, according to 81% of survey respondents. This is followed by cost, reliability and size.

The DRV7308 GaN IPM addresses these key challenges. The integrated device enables more than 99% inverter efficiency by integrating TI’s GaN technology. In addition, the high integration, combined with its efficiency, can reduce solution size by up to 55%, eliminating the need for an external heat sink. It also offers optimized acoustic performance and lowers system costs, TI said. The GaN IPM will be on display at PCIM Europe, June 11-13 in Nuremberg, Germany.

Addressing the need to meet worldwide efficiency standards for appliances and HVAC systems such as SEER, MEPS, Energy Star and Top Runner, the DRV7308 helps engineers meet these standards to deliver more than 99% efficiency and improve thermal performance, with 50% reduced power losses compared to existing solutions, according to TI.

Efficiency standards are increasingly stringent and designers around the globe are striving to meet those standards to support global environmental and sustainability goals, said Giovanni Campanella, general manager for appliances, building and factory automation at TI. “We want to be good stewards of our energy footprints. My team discusses on a daily basis with customers how we can help them meet those standards and the customers’ demand for systems that are reliable, compact and more affordable.”

For engineers, the challenge is to design smaller motor drives that are more reliable and energy efficient and without adding cost, Campanella said. A lot of the technology solutions require tradeoffs between one or more consumer priorities and the introduction of the new device, the DMV7308, will enable designers to address those challenges and design motor drive systems that deliver all consumer expectations and operate at a high efficiency, while also reducing system costs, he added.

Thanks to GaN technology, the new GaN IPM delivers high power density in a 12 × 12-mm QFN package, claiming the industry’s smallest IPM for 150-W to 250-W motor-drive applications.

The DRV7308 also is reported to deliver industry-low dead time and low propagation delay, both less than 200 ns, enabling higher pulse-width modulation (PWM) switching frequencies that reduce audible noise and system vibration. Together, in combination with the higher power efficiency and integration, the DRV7308 also reduces motor heating, which can improve reliability and extend the lifetime of the system.

Those two metrics, low dead time and low propagation delay, translate into higher PWM switching frequencies that can reduce audible noise and system vibration, and enabled by GaN, the new device delivers higher power density, which when coupled with high efficiency can eliminate the heat sink, said Dung Dang, general manager, for brushless DC motor drives product line, at TI.

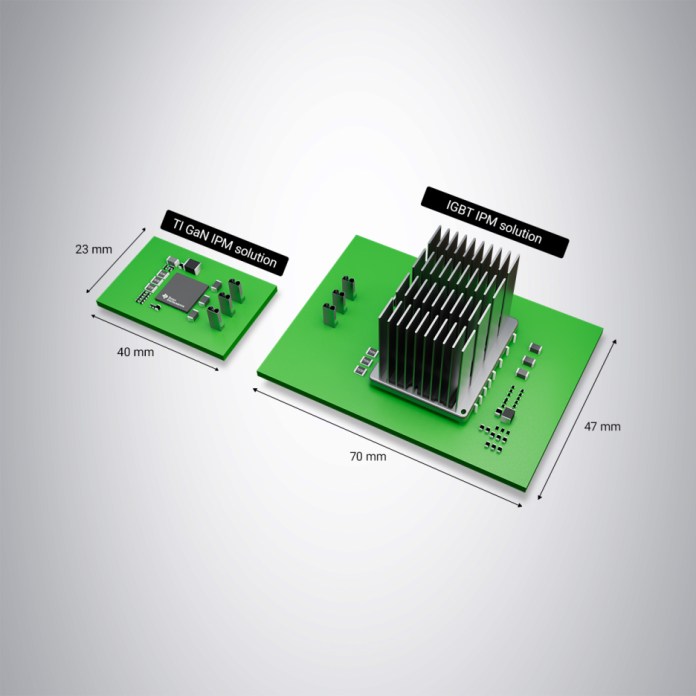

This results in motor drive inverter PCB size reduction of up to 55% compared to IGBT and MOSFET solutions today, Dang added.

The IPM also integrates a current sense amplifier, protection features and inverter stage to further reduce size and cost.

Figure 2: PCB size reduction of the DRV7308 compared to 250-W IGBT solution (Source: Texas Instruments Inc.)

The GaN FETs also offer a 50% reduction in switching losses compared to MOSFET and IGBT solutions and that ultimately improves thermal performance, helping to achieve a new level of 99% inverter efficiency, Dang said.

Higher efficiency is what every appliance system designer is trying to improve, he said. “This graph (See Figure 3) illustrates the efficiency comparison between a TI GaN IPM, represented by the line on top versus, and an existing IGBT solution today. We’ve been able to show a 1.9 to 2.6% improvement in the motor efficiency across the different level loads.”

Dang cited one example why this efficiency is so important to meet higher standards. The new SEER rating of 14 for HVAC systems typically requires system efficiency of 85%, compared to the previous standard at only 80%, he said.

“The 99% efficiency achieved with the DVR7308 enables a system level efficiency of 85% without having to increase the motor cost, which in turn helps the system cost because the design of the motor in this application plays a major role in the overall system cost,” Dang explained.

“The reliability aspect is also enhanced with GaN,” he said. “The life of the motor itself depends on the temperature that it operates at; the higher power efficiency and integration of the features of the DRV7308 reduces the motor’s heating, which can improve the reliability and extend the lifetime of the system.”

The addition of integrated short circuit protection and overcurrent protection for the motor drive also improves system reliability, he said.

Pre- production quantities of the DRV7308 GaN IPM, available in a 12 × 12-mm, 60-pin QFN package, are available for purchase now on TI.com. Pricing starts at $5.50 in quantities of 1,000. TI has additional GaN IPMs under development to meet the needs of higher and lower power applications.

An evaluation module and a 250-W motor inverter reference design are available. The DRV7308EVM evaluation module is priced at $250. Click here for more information about TI’s GaN IPMs.

TI at PCIM Europe 2024

In addition to the DRV7308 GaN IPM, TI will highlight other new products and solutions that enable sustainability with high-voltage technology in hall 7, booth #652. One highlight is an electric vehicle (EV) propulsion system demo. TI, with EMPEL Systems, is demonstrating a new 800-V, 750-kW SiC-based scalable traction inverter system for EV six-phase motors, using TI high-performance isolated gate drivers, isolated DC/DC power modules and Arm Cortex-R MCUs.

TI will also participate in technical sessions. These include the Markt & Technik (“Will SiC ultimately Hold its Own against GaN?”) and Bodo’s Power Systems (“GaN Wide Bandgap Design, the Future of Power) panel discussions.

Advertisement

Learn more about Texas Instruments