Texas Instruments (TI) Inc. has unveiled six new power modules that deliver benefits in power density, efficiency and thermal performance, while reducing size and electromagnetic interference (EMI). These improvements are thanks to TI’s new proprietary MagPack integrated magnetic packaging technology, shrinking the size of the power modules by up to 50% compared to previous generations and up to 23% compared to competing modules. They also deliver higher power density and efficiency while maintaining thermal performance.

The integrated magnetic packaging technology has been in the making for nearly a decade at TI’s Kilby Labs. It includes an integrated power inductor with proprietary newly engineered material. The technology enables the power modules to meet some of the biggest design challenges faced by power designers, delivering a new power module design that does not require tradeoffs in performance, while helping designers reduce design complexity, size and component count.

“The push for more power in smaller and smaller spaces eventually reaches the physical limitation of the chip size itself and the inductor density, so we needed to look at other ways for power designers to be able to achieve that goal,” said Roja de Cande, product line manager for wide Vin buck switching regulators at TI.

Power density and low EMI are the key advantages of the technology, de Cande said. Miniaturization is a continuing trend and pushing more power in smaller spaces is not only a key power challenge, but one that TI will still be innovating for decades to come, she said, and using low EMI products will help designers lower their system cost and meet their objectives quicker.

Power modules are designed to simplify power designs and save board space by combining a power chip with a transformer or inductor in one package. “The global demand for power is increasing across every sector and is continuing to place mounting pressure on the designers to find solutions that not only achieve more with less but also do that while saving time and money,” de Cande said. “Our industry’s answer to its challenge has long been power modules to save valuable board space, by combining a power chip together with the transformer and inductor in one package.”

“With a new approach to packaging, our power modules enable designers to achieve previously impossible levels of performance in a world where space allocated to power is shrinking year over year,” she said.

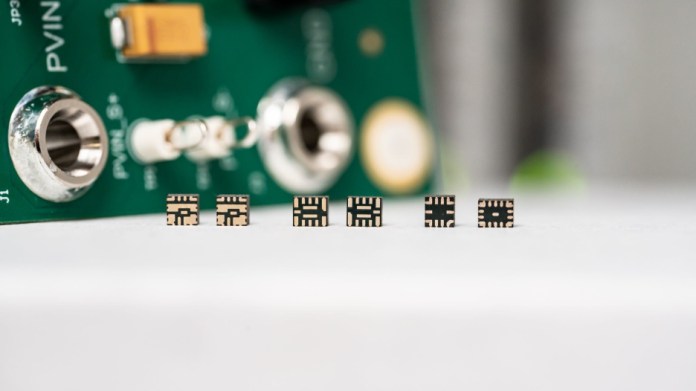

TI launches six power modules with its new MagPack magnetic packaging technology. (Source: Texas Instruments Inc.)

Innovative packaging

TI’s power modules leverage an exclusive 3D package molding process, enabling the MagPack packaging technology to maximize the height, width and depth of the power modules to push more power in a smaller space.

TI believes innovative packaging is reshaping the industry. “TI’s new MagPack packaging technology is inherently different because nothing like that exists in the market,” said Anton Winkler, systems engineer and power modules technologist at TI. “The MagPack packaging technology leverages TI’s exclusive 3D package molding process to maximize the usable package area in height, width and depth of the power module.”

Winkler further explained that the power modules with an integrated power inductor and proprietary engineered material achieves the tightest integration of silicon packaging. This translates into higher power density, lower temperature and radiated emissions as well as reduced system power losses and board space.

Although Winkler could not share a lot of details about the proprietary process, he said by using the 3D package molding process where the inductor is molded around the silicon it helps improve the performance, dramatically shrink the size of the power modules and help with EMI performance.

“Being able to use packaging to shrink the module size while improving performance levels is fundamental to address the design demands of countless applications that shrink year over year,” Winkler said.

He also said by pushing the size smaller while increasing efficiency at the same time, it sets TI apart from the competition. In addition, the packaging technology is manufactured at TI’s internal packaging and test facilities, which gives customers an added benefit of secure supply.

New power modules with MagPack

Aimed at industrial, enterprise and communications applications, these power modules also claim good thermal performance by efficiently removing heat and deliver ease of use thanks to the integration of the inductor. They also offer reduced EMI with a fully shielded package. It is not just the inductor that is shielded, it is also the die and switching node, all enclosed in a shielded package.

The lineup includes the following six products.

- TPSM82866A (2.4-5.5 V): 6-A step-down module with integrated inductor and 13 fixed VOUT options in a 2.3 × 3-mm package.

- TPSM82866C (2.4-5.5 V): 6-A step-down module with integrated inductor and I2C interface in a 2.3 × 3-mm package.

- TPSM828303 (2.25-5.5 V): 3-A step-down module with integrated inductor and noise-filtering capacitors in a 2.5 × 2.6-mm package.

- TPSM82816 (2.7 V to 6 V): 6-A step-down module with adjustable frequency and synchronization in a 2.5 × 3-mm package.

- TPSM82813 (2.75 V to 6 V): 3-A step-down module with adjustable frequency and synchronization in a 2.5 × 3-mm package.

- TPSM81033 (1.8 V to 5.5 V): 5.5-V, 5.5-A valley current limit boost module with power good, output discharge and pulse-frequency and pulse-width modulation control in a 2.5 × 2.6-mm package.

TI claims three of the six new devices—the TPSM82866A, TPSM82866C and TPSM82816—are the industry’s smallest 6-A power modules, providing a power density of nearly 1 A per 1 mm2 of area. These tiny power modules also reduce EMI radiation by 8 dB, while improving efficiency by up to 2% compared to previous generations. The TPSM82816 also delivers up to 4% better efficiency compared to previous generations, 17% lower thermal resistance and a 10° higher safe operating area.

Florian Samson, TI’s product line manager for low-voltage buck switching regulators, said the small size and improved density of the new power modules are particularly attractive to customers with strict application height and space requirements. “For example, the size benefits are especially important for applications such as optical modules for data centers where being able to minimize the footprint of the power components allows more board space for processing.”

Preproduction quantities of the power modules with MagPack packaging technology are available for purchase now on TI.com. Evaluation modules (TPSM81033EVM-035, TPSM82866AA0PEVM, TPSM82866CA3PEVM and TPSM828303PEVM-058) are also available, starting at $49. Additional power modules are planned, including with integrated capacitors to meet different application needs.

Advertisement

Learn more about Texas Instruments