Panasonic recently announced the launch of the world’s first ultra-small lithium-ion battery to come in a subminiature, cylindrical shape custom made for the latest generation of wearable electronic devices. Weighing just 0.6 grams, Panasonic’s CG-320 is a mere 20-mm long and only 3.5-mm in diameter. The pin-shaped battery unit supplies 3.75 volts with a capacity of 13 mAh.

According to Dennis Malec, Senior Applications Engineer for Panasonic Industrial Company, the development of the CG-320 was driven by the demands of its OEM customers, who now have a whole new class of devices in advanced stages of development. Examples include wearables, such as electronically enhanced spectacles, hearing aids, health monitors, and also electronic styli that, due to their form factor, all require tiny pin-shaped batteries rather than the traditional coin-shaped miniature batteries now in use. What many of these units have in common is that many will use near-field communications (NFC), such as Bluetooth, to establish data links between the new class of wearables and the smartphones with which they work.

Figure 1: Positioning of Panasonic’s CG-320 in electronic styli, smart glasses, and health monitors.

Up until now, the challenge in preventing these devices from being produced and sold has been powering them. The CG-320 eliminates that impediment. As component parts of wearable devices, these new batteries will be in close proximity to users. For this reason, safety was the first consideration in the minds of Panasonic designers, and safety is assured by two primary factors.

The first is energy density. The basic electrochemistry of the CG-320’s design makes it possible to cram a lot more than 13 mAh into the unit had its designers allowed, but built-in constraints limit charging capacity to that level and not beyond.

The second safety factor is the unit’s exterior stainless steel can within which the battery is contained. The steel can has a rigid construction and prevents swelling unlike other rechargeable cells. This feature not only isolates the chemical components, but also provides dimensional stability. This is important, considering that the batteries will be used in devices that are likely designed to be as small and light as possible, and will, nonetheless, be exposed to all the stresses of the users’ working or playing environment.

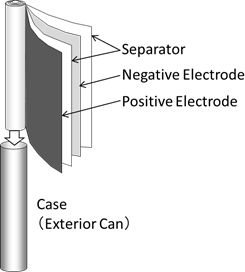

As seen in Figure 2, the package of the negative electrode, the positive electrode, and the separator that sits between them evoke the classical look of a spirally constructed capacitor. With this configuration, many square centimeters of electrode-to-electrode interactive area are packed into the small form of the battery’s case by means of the three components wrapping around its central axis.

Figure 2: Block diagram of Panasonic’s new series of subminiature lithium batteries. The spiral wound design enables higher discharge due to the increased surface area of the electrodes.

The challenge in bringing the CG-320 to market was to “downsize” the elements present in much larger units to a size necessary to fit into this new, subminiature form-factor. The manufacturing challenges were formidable, but Panasonic’s experience with the high-precision manufacturing processes involved in producing the tiny coin-shaped batteries now so common in conventional electronic products went a long way towards meeting this challenge.

The new pin-type batteries can be used repeatedly, and it is unlikely that these highly reliable batteries will need replacement during the life-cycle of the device it powers. It is anticipated that, because of the very low currents involved, OEMs may choose to make inductive charging the preferred method.

Mass production begins in April 2015, and the CG-320 is available now for companies interested in purchasing in large volumes. Other variations of the device are now under development. The CG-425 will be 4.5 mm in diameter, 25 mm long, weigh 1.0 grams, and sport a capacity of 30 mAh. A sister product, the CG-435, will be the same diameter as the CG-425, but it will be a bit longer and heavier at 35 mm and 1.4 grams, and its capacity will be a much larger 50 mAh. All units in this series will provide 3.75 volts.

It is also anticipated that once these new batteries become available to the design community, it will be possible to redesign many types of medical and dental probes and instruments now in use. The electrical cord that, by necessity, must now be used to establish communication between the probe and the central unit can be eliminated, and “cutting the cord” through near-field communications will make them safer and more convenient.

Advertisement