By Maurizio Di Paolo Emilio, contributing writer

The industrial sector is heading toward complete digitalization, and power management is playing a significant role in the industry’s transformation to smart factories and industrial internet of things (IIoT). Industry 4.0 not only promotes new technologies and intelligent products, but also expands the production sector with new business models through mobile solutions, such as wireless nodes.

Energy management must meet design challenges as the industrial sector evolves and the convergence of IoT, data analysis, and cloud computing leads to new complex and connected industrial systems and ecosystems similar to the evolution of electric and autonomous vehicles. Environmental considerations such as CO2 reduction, cost challenges, and the evolving regulatory framework make efficient energy management a vital part of the industry.

The power management IC market is forecast to grow at a compound annual growth rate (CAGR) of 6.13% from 2016 to 2022. Power management ICs (PMICs) provide a highly integrated, high-performance architecture for a wide range of application categories, such as networking, telecommunications, automotive, and consumer electronics. PMICs offer various integrated options, such as protection, system control, battery management, audio functions, and other application-specific specifications.

Here are 10 products from leading providers that deliver the efficiency and flexibility needed for Industry 4.0 segments, including smart factories, smart manufacturing, and IIoT.

Maxim Integrated Products Inc., MAX20075 step-down converter

Maxim Integrated has extensive experience in addressing power requirements for a variety of industrial sectors. These solutions can manage different battery-based applications, which can be used in sensing solutions for the IoT network. Compact dimensions, high operating efficiency, low quiescent current, and reduction of electromagnetic interference (EMI) are the key features of Maxim’s power ICs.

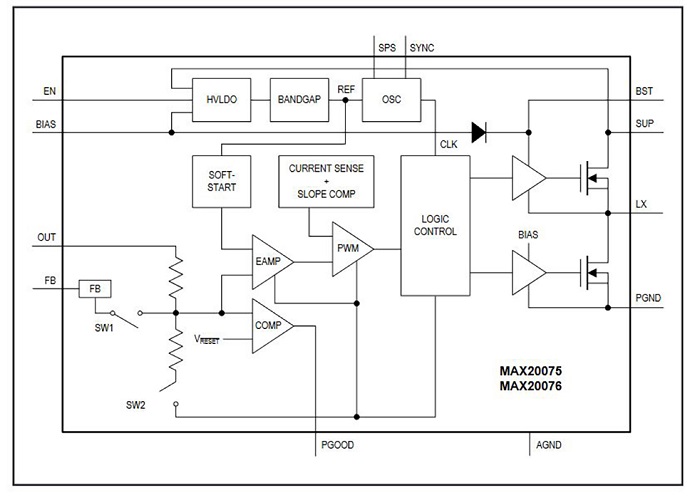

Fig. 1: Maxim’s MAX20075. (Image: Maxim Integrated)

One example is the MAX20075, a synchronous step-down converter with low quiescent current. The device automatically enters skip mode at light loads with ultra-low quiescent current of 3.5 μA at no load. The MAX20075 offers high peak efficiency of 91% for applications that are always-on, and a tolerance of 40 V of overload (Fig. 1 ). The device can be used in a variety of industrial applications, as well as automotive ones. It offers two fixed 5-V and 3.3-V output voltages. The frequency is set internally at 2.1 MHz, which allows for small external components, a reduction in output ripple, and attenuation of AM interference. The device offers pin-enabled spread-spectrum-frequency modulation to minimize EMI-radiated emissions due to the modulation frequency.

Texas Instruments Inc., TPS62840 & TPS650250 PMICs

Texas Instruments (TI) satisfies power management challenges through a series of solutions for any application, from automotive to high-voltage designs based on gallium nitride (GaN). The combination of operating parameters allows the creation of innovative solutions.

The TPS62840 is a synchronous step-down converter characterized by a low quiescent current (IQ ), typically 60 nA. This switching regulator makes it possible to increase battery life in battery-powered industrial and consumer applications, such as those in the IoT sector, network infrastructure, and wearable devices.

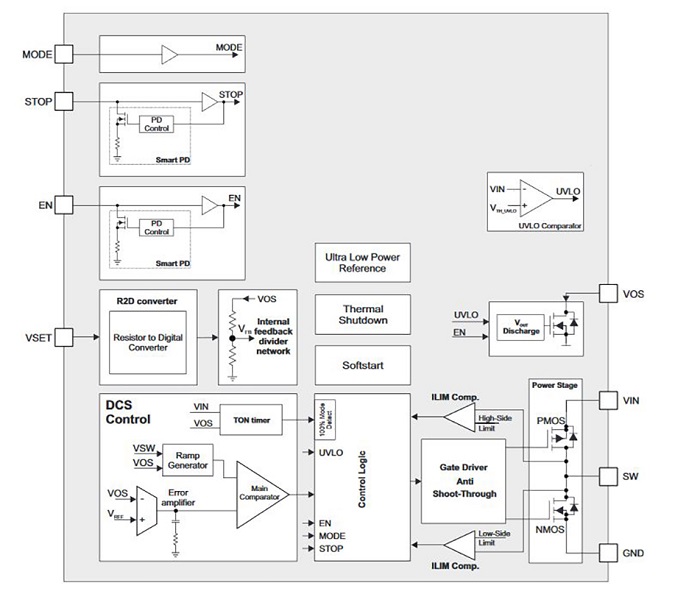

Fig. 2: A block diagram of the TPS62840. (Image: Texas Instruments Inc.)

TI PMICs provide industrial system power solutions for processors such as Sitara, NXP i.MX, Intel Apollo Lake/Skylake, and Xilinx/Altera FPGAs in home and factory automation, human-machine interfaces, and other industrial applications. Controller-based PMICs are also available to solve thermal problems through various packaging solutions.

One solution is the TPS650250 integrated PMIC, which is suitable for applications that require multiple power rails. It offers three highly efficient step-down converters designed to provide network voltage, peripherals, I/O, and memory buses in a processor-based system. All three step-down converters, controlled by the MODE pin, enter low-power mode at light load for maximum efficiency or operate in PWM mode with fixed-forced frequency.

The TPS650250 device integrates two 200-mA general-purpose LDO voltage regulators. Both LDOs operate with an input voltage range of 1.5 V to 6.5 V. The output voltage of all the rails can be set with an external resistance divider and enabled with an input pin. Furthermore, a 30-mA LDO is typically used to supply power to an always-on rail.

ROHM Semiconductor, BD71847AMWV PMIC

Most industrial devices currently in use operate at high voltages between 24 V and 72 V, which is incompatible with the 3.3 V to 12 V required for electronic circuits. ROHM’s industrial DC/DC line includes products that support a wide range of input voltages with high-efficiency output voltages.

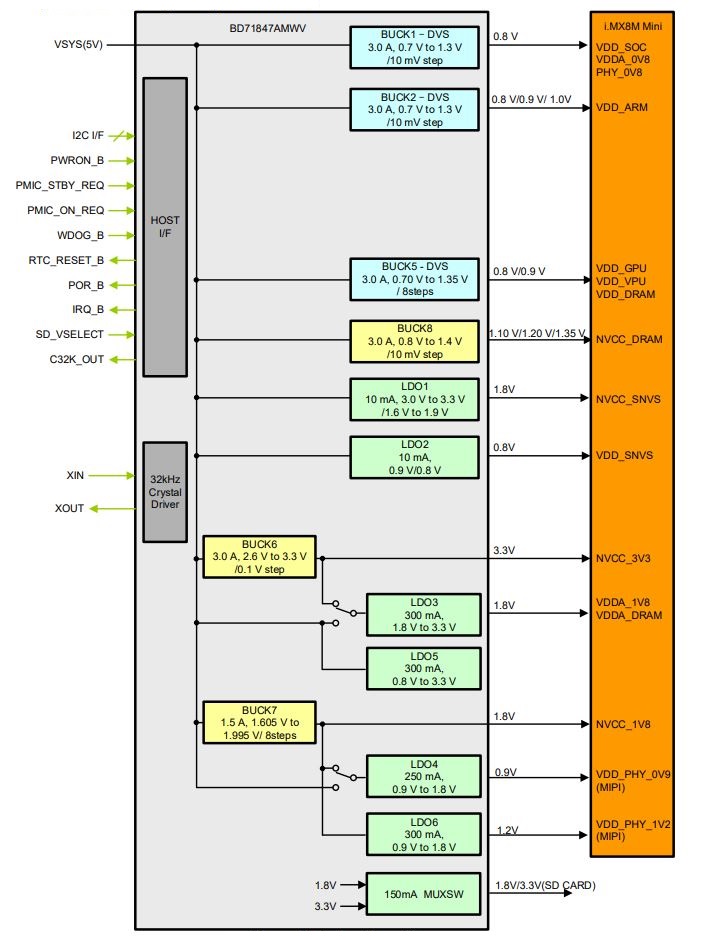

The BD71847AMWV is the latest addition to ROHM’s PMIC product portfolio, designed specifically for NXP’s i.MX processors. In addition to DC/DC converters, which at 95% efficiency are among the best in the industry, ROHM’s PMIC features a programmable sequencer for flexible power control and management, a hardware control interface for i.MX 8M Mini, sleep clock buffers, and protection functions. The PMIC integrates six DC/DC buck converters, six LDO regulators, a 1.8-V/3.3-V power switch for SDXC cards, 32-kHz crystal drivers and output clocks, protection and monitoring circuits, as well as a programmable sequencer and the control logic for power status.

Fig. 3: A system power map and a typical application circuit of the BD1847AMWV. (Image: ROHM Semiconductor)

ROHM’s high-efficiency step-down switching regulator, the BD9106FVM-LB, is designed to produce a low voltage, including 1 V from a 5-V power supply line. It employs a current-mode-control system to provide faster transient response to a sudden change in load.

Analog Devices Inc., LTC3372 controller and LTM4700 regulator module

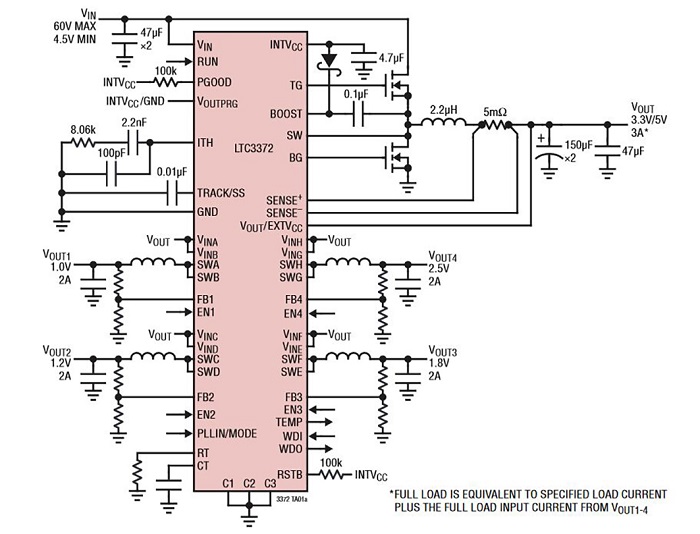

The LTC3372 from Analog Devices Inc. (ADI) is a highly integrated power management solution for systems that require multiple low-voltage outputs generated by input voltages up to 60 V. The device offers a 60-V synchronous buck switching controller and four configurable synchronous buck regulators. The LTC3372’s buck controller provides an input range from 4.5 V to 60 V and drives an N-channel MOSFET power stage. Each buck channel can be programmed to adjust a minimum output voltage of 0.8 V, with a configurable output up to 4 A.

Fig. 4: A block diagram of the LTC3372. (Image: Analog Devices Inc.)

In addition, ADI offers a range of µModule Power products by Linear, which includes the LTM4700 module that enables increased density for servers in data centers, with a minimum impact on system size and cooling costs. The highly integrated component-on-package includes memory, data conversion circuits, and a digital interface.

Microchip Technology Inc., MCP19122/3 buck controllers

Microchip Technology has a rapidly expanding portfolio of DC/DC controller products for the mobile and industrial device markets. The Digitally-Enhanced Power Analog (DEPA) controllers represent the best products in the class designed to provide high efficiency in a small form factor.

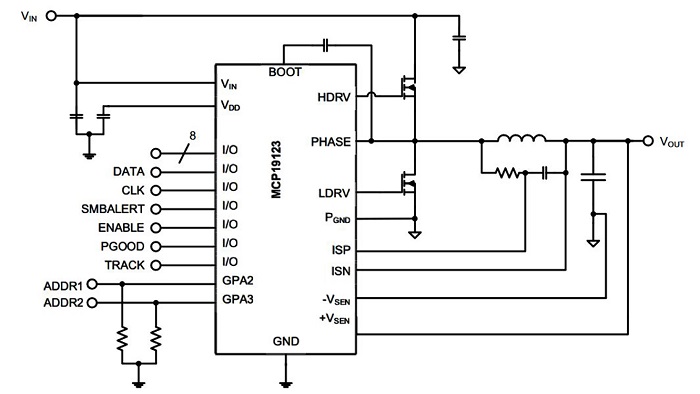

The DEPA MCP19122 and MCP19123 buck controllers can accept a high-voltage input, up to 42 V, and simultaneously adjust a wide range of output voltages, from 0.3 V to 16 V, without the need for an external component or driver. Multiple outputs in parallel offer system redundancy for high-power applications. The MCP19122/3 are suited for high-performance intelligent power applications.

Fig. 5: A block diagram of the MCP19122/3. (Image: Microchip Technology Inc.)

The integrated PIC microcontroller can dynamically adjust operating frequency, over- and under-voltage block threshold, current limits, and soft-start, as well as program the output voltage, output current, and maximum duty cycle. Improving integration in larger systems, the device can synchronize with an external reference clock and voltage, or provide its clock and internal references to other devices for synchronization. In servers or communications equipment, this allows enhancements without discontinuity and accurate tracking of energy consumption through the board.

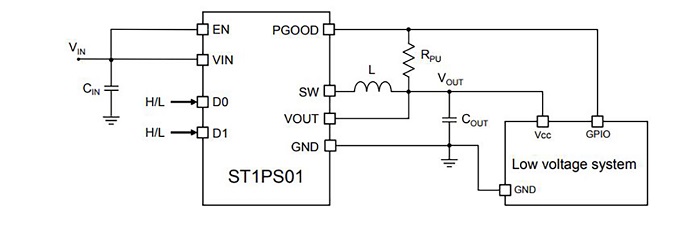

ST Microelectronics, ST1PS01 DC/DC converter

ST Microelectronics’ ST1PS01 DC/DC converter is an attempt to overcome the trade-offs between form factor and energy efficiency. The converter, housed in a flip-chip package (1.14 x 144 mm), provides an output current up to 400 mA with an input voltage between 1.8 V and 5 V. Thanks to the enhanced peak current control (PCC) and advanced design circuitry, the ST1PS01 minimizes the quiescent current and achieves a very high-efficiency conversion using only a 2.2 µH inductor and two small capacitors.

Fig. 6: Application schematic of the ST1PS01. (Image: ST Microelectronics)

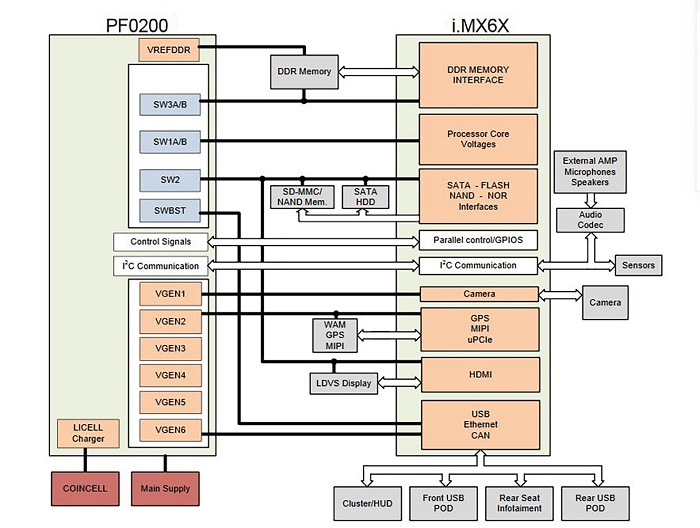

NXP Semiconductors, MMPF0200 configurable PMIC

NXP Semiconductors offers PMIC solutions to support various industrial applications. The key feature of these PMICs is their flexibility in programming with high levels of integration and efficiency. PMICs can be used in a wide range of devices to extend battery life and reduce energy dissipation while eliminating many external components. Advanced features, such as precise power sequencing and low-dropout voltage, ensure optimized energy consumption.

Fig. 7: A block diagram of the MMPF0200. (Image: NXP Semiconductors)

The MMPF0200 with SMARTMOS technology offers a configurable and programmable architecture. The MMPF0200 can supply energy for a complete industrial system through four buck converters, a boost regulator, six linear regulators, and a button charger. The device is particularly suitable for the i.MX 6SoloLite, i.MX 6Solo, and i.MX 6DualLite versions of the i.MX 6 family of devices.

Conclusion

Power management aims to optimize production costs, reduce CO2 emissions, and ensure a safe and reliable supply. In an Industry 4.0 environment, flexible production capacity and energy efficiency require flexible integrated systems.

The key to energy management is using high-efficiency DC/DC solutions, ensuring that the processor is in a low-power standby mode as much as possible, and reducing wireless communications to the minimum. In addition, the selection of the correct active and passive components will significantly contribute to reducing the energy profile of the sensor nodes used in the various industrial subsystems.

Advertisement

Learn more about Electronic Products MagazineMaxim IntegratedTexas Instruments