The Rittal Corporation , subsidiary of Rittal GmbH & Co. KG, is paving the path for the manufacturing and design of Industrial and IT infrastructure enclosures, racks, and accessories by setting the standards in Industry 4.0 through an aggressive embrace of innovation. Rittal’s approach helps smart factories achieve Industrial Internet-of-Things connectivity by adopting a modular structure to lead products from conception through implementation and manufacturing.

In the unfolding fourth industrial revolution, embedded sensors, data-controlled equipment, and automated systems are granting managers unprecedented real-time visibility of performance indicators, allowing them to fine-tune the production process to its utmost lean capacity or avert potential disasters. Companies abiding by the Industry 4.0 philosophy are more likely to overcome unexpected logistical interruptions and miscommunications caused by data disconnects, thus minimizing down-time and maximizing lean manufacturing.

Typically, the accelerated manufacturing present in the smart factories results in a 50% cost savings over conventional manufacturing, shorter throughput times, increase flexibility, shorter delivery times, and most importantly, cost transparency and control.

“More and more people are starting to understand the Industrial Internet of Things concept and what cloud computing is,” said Troy Miesse, Solution Engineering Manager for Rittal. “We are in the middle of applying Industry 4.0, at the forefront of the smart factory. In that environment, everything is connected—not just the machines, but corporate information systems as well as the humans who rely on them.”

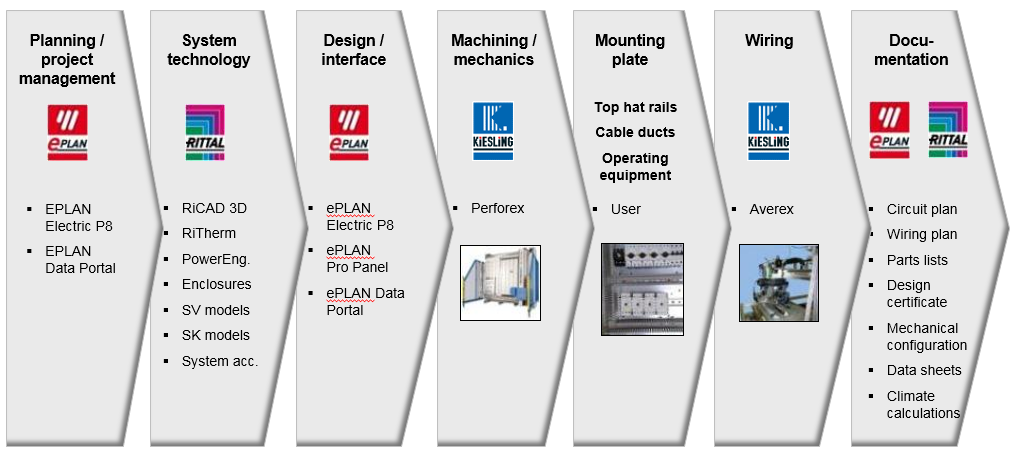

Together with its sister companies — e-PLAN, Cideon, and Kiesling — Rittal provides an optimized value chain that automates repeated processes and streamlines design changes. “If you need to change a component, you don’t only change it upfront in the design but on the purchasing side, as well – the documentation for the purchase requisition, the data for the panel layouts, the data for the fabrication/ assembly and the processes needed out on the factory floor to enable it all.” In effect, the precision instilled by this practice extends from the factory floor through the purchasing department by updating the BOM in real-time and on-the-fly.

With a large portfolio of products spanning across planning/project management, system technology, design/interface, machining/mechanics, mounting plate, writing, and documentation, Rittal looks to help companies compete in the Industrial IoT Era with an Industry 4.0-approach to information infrastructure.

To learn more, visit Rittal

Advertisement

Learn more about Electronic Products Magazine