Transparent conductive sheets (on glass or other substrates) are used in a variety of applications including touchscreens, displays, lighting, photovoltaics, etc. This is already a large and well-established business. Indeed, the nondisplay sector alone (includes touch) is set to generate $1.4 billion in 2014 at the sheet level. This is a fast-growing sector with a 6% CAGR between 2014 and 2024.

This market is in a transformation phase — the needs are changing and so are the solutions. The IDTechEx report Transparent Conductive Films (TCF) 2014-2024: Forecasts, Markets, Technologies analyses all the key trends shaping the industry, assesses all the key existing and emerging solutions, provides detailed interview-based business intelligence on players and offers granular market forecasts.

Changing needs

The key trends changing the needs are a tendency towards ultra-low sheet resistance values and mechanical flexibility. New applications such current-driven OLED lighting and photovoltaics are appearing that demand sheet resistance values substantially below the 150-250 ohm/sqm required by existing capacitive touch technologies; while touch applications themselves are also growing in size.

Fig 1: Touchscreen applications are growing in size. (Source: IDTechEx, various.)

Mechanical flexibility is also a growing trend. In the short term, robustness will be phased in, followed by devices with a fixed curvature before bendable versions are launched.

Fig 2: Robust, curved and/or flexible devices are emerging. (Sources: Samsung, HP, Fujitsu, Solvay, and others.)

The cost pressures in the industry are also intense, given that solutions and suppliers are many and buyers few. At the same time, a number of key end applications are fast becoming commoditised thus cost is becoming a key differentiator. This in turn translates into a cost pressures onto the entire value chain.

Multiple solutions

Indium tin oxide (ITO) is the incumbent solution today, controlling almost the entirety of the market. ITO-on-glass gives the best results, but requires a high annealing temperature and is rigid. ITO-on-glass has fast been losing market share in the touch screen sector to ITO-on-PET, which has a higher sheet resistance but offers lower cost, increased robustness and limited flexibility. This shift, coupled with the increase in demand from the touch sector (particularly large-sized ones), has convinced key suppliers to heavily invest in increasing ITO-on-PET production capacity worldwide.

ITO-on-PET itself is also facing pressures. The uncertainty associated with the cost of raw indium is forcing many users to consider alternatives. The limited sheet resistance (150-350 ohm/sqr) will also not readily meet the needs of emerging applications. ITO-on-PET offers limited flexibility, but it does not survive when bent too much and/or too many times. These market forces are opening up the space for ITO alternatives.

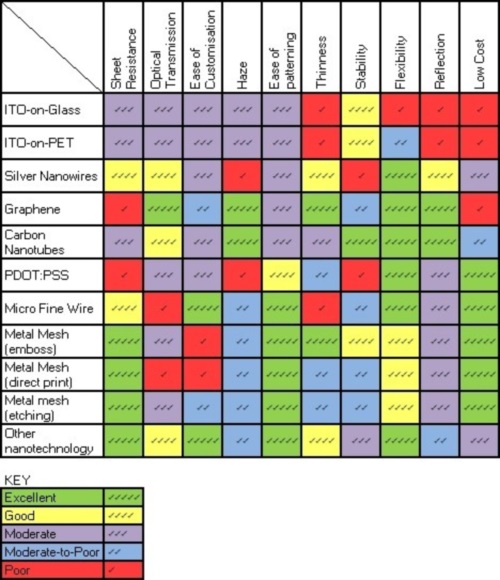

Many ITO alternatives are also emerging on the market. The multiplicity of the solutions is such that it represents a decision-making nightmare for end users. Key emerging solutions include silver nanowires, carbon nanotubes, PEDOT, graphene and a variety of metal mesh technologies. No single technology is a one-size-fits-all solution satisfying all the emerging needs.

Graphene is a late entrant onto the scene and is currently over-priced and under-performing. It is however a technology that is witnessing large R&D investment and rapid innovation. Silver nanowire is a commercially well-funded solution and has already demonstrated initial product acceptance from a variety of end users. Carbon nanotubes offer a mediocre sheet resistance but promise to minimise stack layers. PEDOT has come a long way in terms of sheet resistance but is today only on a par with existing ITO-on-PET solutions. Metal mesh offers low sheet resistance, low cost and the potential to skip the patterning step. There are multiple ways of manufacturing metal mesh TCFs and supplier numbers are fast multiplying. In many instances, however, yield is still a sticky question mark. The table below benchmarks various technologies on the basis of several important parameters, demonstrates that there exists trade-offs.

Fig 3: Benchmarking different TCF and TCG technologies on the basis of sheet resistance, optical transmission, ease of customisation, haze, ease of patterning, thinness, stability, flexibility, reflection and low cost. The technology compared include ITO-on-Glass, ITO-on-PET, silver nanowires, graphene, carbon nanotubes, PEDOT, metal mesh, and other nano-based solutions. (Source: IDTechEx.)

Full analysis and assessment

Transparent Conductive Films (TCF) 2014-2024: Forecasts, Markets, Technologies provides a detailed and complete assessment of incumbent and emerging technology solutions. For each technology, IDTechEx assess production method, key cost drives, key figures-of-merit including sheet resistance, optical transmission, haze, flexibility, surface smoothness, stability, etc. IDTechEx provides a SWOT analysis for each technology. Moreover, IDTechEx identifies all suppliers globally, outlining their commercialisation progress.

IDTechEx has built a detailed, granular and accurate market forecast model. IDTechEx has used its forecast model to provide the following key market data charts:

Ten-year forecasts in unit sales or market value, for TCF and TCG by area and value for the following applications:

• Mobile and smart phones

• Notebooks and touch notebooks

• Montiors and touch monitors

• Tablets

• OLED lighting-

• Organic phototovotaics

• Dye-sensitised solar cells

• Electroluminescent displays

Ten-year market forecasts in area, market share, and value for the following technologies:

• ITO-on-Glass

• ITO-on-PET

• Silver nanowires

• Carbon nanotubes

• Graphene

• PEDOT

• Metal mesh

Market intelligence

100+ companies are profiled including 35+ detailed profiles based on direct interviews and company visits. The rest are profiled based on conference attendance, tradeshow visits, patent searchers and/or web searches.

For more information, see www.IDTechEx.com/tcf

Advertisement

Learn more about IDTechEx