By Maurizio Di Paolo Emilio, contributing editor

Many features come together to make a useful wearable device. Form factor, design, and energy efficiency are essential to realizing devices that not only do their job correctly but are also comfortable, attractive, and easy to use, offering new ways to improve our productivity, health, and lifestyle. The goal of designers of always-on wearable and internet of things (IoT) devices is to extend battery runtime while shrinking the form factor, which can be accomplished with tiny, highly integrated power management ICs (PMICs).

Optical-sensing accuracy in wearables is also a big concern, which is impacted by a variety of technical factors, including the choice of PMIC. Ultra-low-power PMICs integrate circuit architecture that optimizes the sensitivity of optical measurements for health applications. The new PMICs enable the highest sensitivity for optical sensing in wrist-worn form factors for more accurate vital-sign measurements, as an example.

In recent years, the number of wearable sensors in circulation has grown exponentially. This is due to various factors ranging from the increase in health-care costs to the growth of “health fanatics” — a lifestyle that is characterized by an obsession with health. Moreover, thanks to the internet, consumers now have easy and almost unlimited access to information concerning their health. The design of reliable solutions in the wearable medical field requires reliable electronics. The high functionality required by devices such as hearables and smartwatches involves a higher consumption of energy.

The continuing trend toward smaller and thinner packages, in turn, requires a new generation of integrated power management circuits that facilitate charging. Conventional batteries that fit wearable technology, such as lithium-ion (Li-ion) cells, may be fine for sensors and other wearable devices with low power demand, but they struggle to keep up with the highest-performing wearable requirements such as speech and gesture recognition, monitoring, and sensing.

The printed-circuit-board (PCB) design for wearable devices requires much consideration both for the choice of materials and a correct layout in compliance with electromagnetic compatibility requirements. Wearable PCBs require much closer impedance control, which is an essential element of the layout resulting in cleaner signal propagation.

PMIC architecture

A typical wearable device architecture includes a system-on-chip (SoC), memory, display, sensors, and power management blocks. A typical power management system includes a charger, various buck converters, and low-dropout regulators (LDOs) for Bluetooth/Wi-Fi connection. In a smartwatch, for example, design challenges are essentially dissipation management and battery sizing. All of this involves an appropriate selection of PMIC devices.

Most systems require a charger and various outputs regulated for common circuit functions — for example, 3.3-V and 1.2-V supply buses for the microcontroller and communication protocols.

A highly configurable, integrated linear loader in the PMIC supports a wide range of Li-ion batteries and includes battery temperature monitoring for added safety. A bidirectional I2 C interface allows designers to configure and monitor device status. The architecture of a PMIC also includes a controller with supervision functionality.

Power supply systems with buck and boost converters are the most efficient. Low-voltage, low-dropout linear regulators are preferred for low-noise devices, but energy efficiency can be a critical factor. An optimal supply system is represented by the exclusive use of switching power supplies. The drawback of this approach is that each switch requires an inductor, thus increasing the PCB space and the size of wearable devices.

As a result, the circuit requires a single power management solution that integrates various power buses using a single-input, multiple-output (SIMO) architecture. By providing multiple outputs, the SIMO approach, together with the low standby current of the controller, extends the battery life of the wearable design. Regulators provide energy with minimal losses, and the architecture eliminates some duplicate components while saving on the bill of materials.

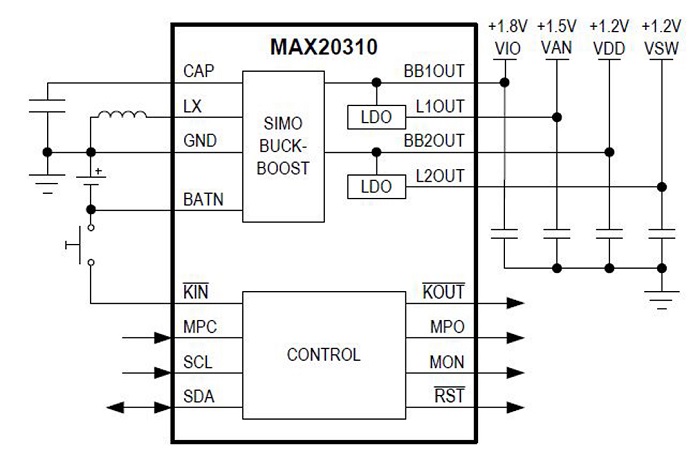

One example is Maxim Integrated’s MAX20310 , an integrated power management circuit that combines two SIMO buck-boost outputs with two LDOs and other power management features such as a sequencing controller. The linear regulators can also function as power switches that can disconnect the inactive load of the system peripherals (Fig. 1 ) to improve the efficiency.

Fig 1: A block diagram of the MAX20310. (Image: Maxim Integrated)

Optical-sensing accuracy

In wearable devices, the accuracy of the optical measurement is influenced by a variety of biological factors that are exclusive to the user and the nature of the design, linked to the stability of the supply voltage. The designers endeavor to increase the sensitivity of optical systems in terms of signal-to-noise ratio (SNR) to cover a wide range of applications. The use of low-quiescent-current regulators leads to design compromises that degrade SNR in terms of ripple or long settling times.

One solution is a highly integrated PMIC such as Maxim’s MAX20345 , which features a buck-boost regulator with a low ripple at high frequency that does not interfere with measurements such as heart rate, blood oxygen (SpO2 ), and glucose levels.

Higher-accuracy measurements can help patients make more informed choices. For example, real-time glucose levels help them make better decisions about the types of food, physical activities, and medication that they require throughout the day.

The optical measurement of heart rate is done using photoplethysmography (PPG), an optical technique that measures blood volume in the artery. Depending on the measurement conditions, the controller can increase performance by up to 7 dB.

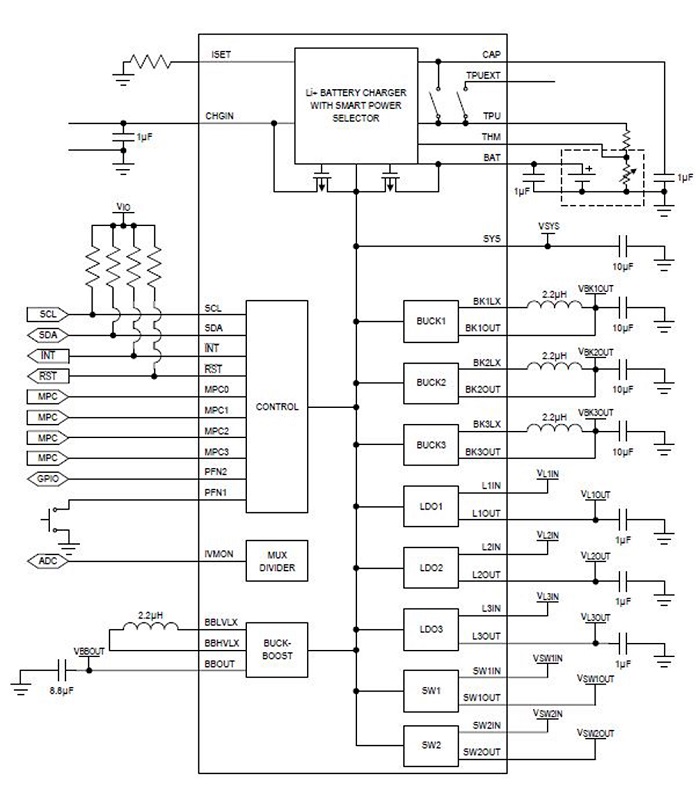

The MAX20345 PMIC integrates a Li-ion battery charger and six voltage regulators, each with an ultra-low quiescent current on the order of 500 nA (Fig. 2 ). The three high-efficiency synchronous buck regulators use a pulse-frequency–modulated (PFM) control scheme. The output voltage of these controllers can be programmed via an I2 C interface up to 0.7 V. In addition, buck regulators support dynamic voltage scaling (DVS), which allows the designer to improve system power consumption further.

Fig. 2: The functional diagram of the MAX20345. (Image: Maxim Integrated)

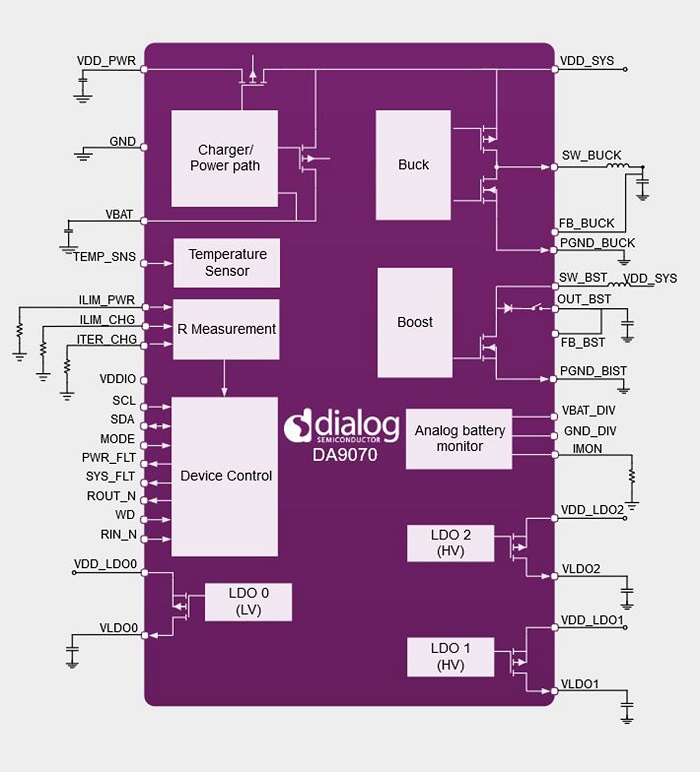

The goal of extending battery life in wearable applications is also a task of Dialog Semiconductor. Its highly integrated and low-quiescent-current DA9070 PMIC integrates a linear charger with a current up to 500 mA to accelerate the charge cycle, a buck regulator, battery monitoring, watchdog, and various protection functions.

The DA9070 offers several power-saving modes to increase battery life. Programmable power states optimize performance in operating modes and extend battery life in storage mode. The integrated high-efficiency boost regulator supports both sensors and display requirements with a wide range of configurable output voltages (Fig. 3 ). The integrated PMIC reduces power management footprint by 25% compared to other discrete solutions.

Fig. 3: A block diagram of the DA907 with a 2.5-V to 5.5-V operating range. (Image: Dialog Semiconductor)

Conclusion

Although ICs are shrinking their physical dimensions, their capacities and complexity continue to increase and put a strain on power sources. Wearable products often require flexible form factors to accommodate the shape and movement of the human body in addition to their small size, which further complicates the design process.

The main objectives of a wearable device design are a compact form factor, low weight, and ultra-low energy consumption. The low power consumption of PMICs both in operating mode and shutdown, together with ultra-low quiescent current, is essential to increase execution times, while the low power consumption of DC/DC converters is necessary for product optimization.

Advertisement

Learn more about Electronic Products MagazineMaxim Integrated