BY TOBIAS PUETZ

Systems Engineer, Factory Automation and Control

Texas Instruments

www.ti.com

For more than half a century, robots have played an ever-increasing role in manufacturing, successfully transforming industries ranging from automobiles to electronics to consumer goods. As their adoption continues, they are evolving to become more connected and intelligent while working more closely and collaboratively with their human counterparts.

This presents a number of challenges for designers who are being asked to add greater functionality, flexibility, range of motion, speed, and precision while, at the same time, improving safety and reliability.

This feature will describe three different classes of robots: industrial, logistical, and collaborative. It will then focus on the design challenges, what parameters are most important to the system, and how to go about selecting components to help meet those challenges.

The expanding role of robots

For over 50 years, robots have brought productivity, cost-efficiency, and improved safety to repetitive task performance. Though their roles have expanded greatly, they can be generally placed into three main categories: industrial, logistical, and collaborative (Fig. 1 ). Each has their respective sensing and safety requirements and best practices.

Fig. 1: Robots for industrial and factory automation can be classified into three main categories: industrial, logistics, and collaborative.

Industrial robots are fixed in place to handle tasks such as welding, painting, picking and placing, and assembly. The controller is usually either in the base of the robot or next to it. They are designed to be quick and accurate with no direct human contact. For safety, they are usually isolated inside fences with added protection, such as floor mats that trip the power when stepped on.

Logistical robots are mobile, are typically used to fetch goods or transport loads in warehouses, and may operate with humans present. As such, they usually have a handler and move within a certain environment using sensors and mapping. Example sensors to help avoid collisions include ultrasonic and LiDAR. The controller is located inside with a wireless interface to a central control center.

Collaborative robots work next to humans, and so they are the most complex. They need particular attention to safety and need to perform fine-tuning tasks or hold an object while a worker inspects it. They require an array of sensors for collision avoidance and failsafe mechanisms to turn off the robot should anything go wrong. They are typically fixed in place but can also be mounted on a vehicle.

It’s clear that for robots to operate in these increasingly complex ways, they must be able to process a great deal of sensing data about the environment, communicate with each other and with centralized control units, and perform control functions that adapt to environmental changes and keep them from harming humans.

Technology requirements for industrial robotics

The three areas of technology that play a major role in robotics are: communication, motor control, and sensing. Robot systems are often built together out of products from several different manufacturers. Therefore, it is necessary that all of these products can be connected either to each other or to the main robot controller. For a design engineer, this means that a system must support multiple protocols, making flexible communication controllers a requirement.

Processors for such control need to provide flexible peripherals, connectivity, and unified software support to cover a wide set of applications. Look for a processor with single or multiple cores to ensure that the right balance of integration, connectivity, and performance is available for every application.

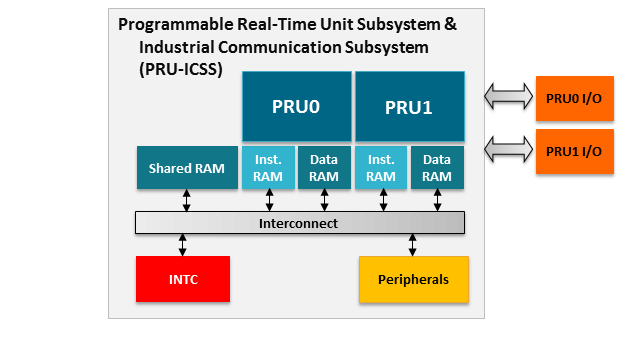

Flexibility is often achieved using external FPGAs or application-specific ASICs, but there are other options to consider, such as a single-chip solution that combines a processor with a programmable real-time unit inside the industrial communication subsystem (PRU-ICSS) (Fig. 2 ).

Fig. 2: Features such as the PRU-ICSS exist as a hardware block inside a processor to support multiple industrial communications protocols.

These exist as a hardware block inside the processor and support multiple industrial protocols like EtherCAT and ProfiNET, among others, which enables designers to build in flexibility and interface to every part of the robot system.

Efficient motor designs needed

As more motors are used in a robot system, motor efficiency becomes critical — not just for large load-carrying motors, but also for smaller, collaborative robots as they increase in usage. Collaborative robots often have the motor control boards integrated into the robot arm; that is why designers need to pay special attention to the thermal management. Therefore, it is not only necessary to select components that are small in size but also to use switches with low switching losses.

Gallium-nitride (GaN) technology is an important design asset here because it greatly reduces switching losses, thereby enabling faster switching speeds while simultaneously facilitating thermal management. To simplify and speed the design process, designers should look for modules that provide a complete solution with optimized layout and efficiency, along with minimum electromagnetic emission and noise for compliance with industrial standards.

Also, support should include EVMs, development boards, and a quick-start toolset to speed design. For specific functions, such as accurate control of precision drives, a vendor’s reference design library may already include an appropriate design.

Using well-supported reference designs speed time-to-market by reducing the chance of design errors while also freeing up designers to focus on their design’s core differentiation and value.

Better sensing in challenging environments

Regardless of whether robot designs are industrial, logistical, or collaborative, sensing is playing an increasing role. For collaborative applications in which sensing systems must be able to not only detect if a human is around but also prevent any possible collision, sophisticated sensor technologies are a core requirement. They must be able to cover a wide range of up to several meters while offering resolutions down to centimeters or even millimeters. Furthermore, multiple sensor systems are needed to cover the complete range from near- to far-field.

Meeting these design requirements is difficult. Common challenges are variable sensing ranges and resolutions, dirty environments, and the difficulty of differentiating between humans and other robots working in the same environment.

The solution is to use multiple sensors systems: capacitive sensing for the near-range (up to 15 cm), infrared sensing for middle-range (15–150 cm) and laser sensing for long-range (>150 cm). However, laser systems come along with a lot of safety restrictions.

These challenges can be solved by using new and advanced sensing solutions, like millimeter-wave radar in the 76- to 81-GHz bands. Sensors operating in this region can detect objects at a range of up to 84 m, with a resolution of 37 cm. Depending on the system requirements, these parameters can also be tweaked for shorter range and higher resolution.

Millimeter-wave ranging sensors also allow velocity measurement of the detected object, and because it is RF, it is robust in the face of environmental conditions such as dust, smoke, fog, rain, sunlight, or darkness.

Another ranging option is a 3D time-of-flight (ToF) system that can, for example, be mounted onto the wall or ceiling and be used for people recognition at manufacturing lines (Fig. 3 ). The system returns a point cloud that can be further processed in software.

Fig. 3: A good 3D time-of-flight (ToF) image sensor combines ToF sensing with an optimized analog-to-digital converter and timing generator with a QVGA resolution to detect people on manufacturing lines and distinguish between objects and between objects and humans.

This gives the end user the ability to not only detect objects but also distinguish between steady objects, robots, and humans. Furthermore, a wide field of view of 87° diagonal, 74° horizontal, and 59° vertical can be covered at an operating range of 4 m. Lastly, such a system can also be used in dark environments because of the usage of near-infrared (NIR) lasers emitting at a wavelength of 855 nm.

Building better robots for the integrated factory

As manufacturing continues to become more highly integrated at all levels, robots will play an ever-increasing role in carrying out a wide variety of assembly tasks that increase production and make the workplace safer for human beings. Traditional industrial robots, logistical robots, and collaborative robots have their jobs to do. So, too, do robot developers as they look for solutions that enable accurate, safe, cost-effective operation from all of them. To that end, designers should also ensure:

- A high-efficiency, high-voltage power supply with circuit protection and low-noise emissions

- Characterization for an extended temperature range

- Fast, precise analog-to-digital and digital-to-analog signal conversion

- Reinforced isolation to meet industrial safety standards

- Control redundancy for safety-critical applications when combined with other ICs

In many cases, it’s smarter to work with a vendor with a wide degree of experience in the design and application of robotic technology in industrial applications. It’s highly possible that they’ve either solved for the various challenges of a design or have the expertise to help uncover a new solution.

Advertisement

Learn more about Texas Instruments