Wearables. The term has become a sensor-charged mantra of both startups and century-old companies. Encompassing more gadgets and devices each year, wearables have made an incredible boom in the electronics industry. Products ranging from smartwatches to sensor-laced clothing are emerging into the market place. The reality is, however, that wearables aren’t just individual gadgets that perform a solitary function. Instead, they represent stepping stones on the way to the connected self, dropped into the Internet of Everything. These items are connected to you, but they go beyond that now—they are also able to connect you to your environment. From their wrist and eyeglass beginnings, they are now resident in stylish jewelry and even embedded under the skin. Wearables help us stay healthy, provide a communications platform spanning social media to battlefield strategic communications and, in their spare time, improve our golf game.

Just How Big is Big?

Researchers have jumped on the proverbial bandwagon to cover where the wearables market is and where it is expected to go in the near-term. IDTech’s new report, for example, Wearable Sensors 2015-2025: Market Forecasts, Technologies, Players, sets the market at more than three billion sensors worth $5.5 billion in wearable technology devices by 2025, 30 percent of which will be emerging sensor types.

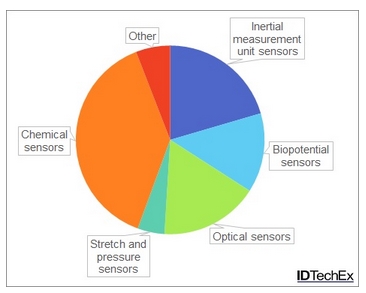

This report calls out 15 sensor types in wearable technology, including inertial measurement units (IMUs) that combine accelerometers, gyroscopes, magnetometers and barometers, optical sensors, wearable electrodes, chemical sensors, flexible stretch, pressure and impact sensors, temperature sensors, microphones, and more.

While sensors alone are estimated to come in at $5.5 billion, IDTech estimates that in all its forms, the wearable technology market will explode to a value of $70 billion by 2025.

Figure 1: Forecasts for the relative market sizes by wearable sensor type to 2020. (Source: IDTechEx Research report)

In addition, hot off the press are two Compass Intelligence reports that set wearables in the enterprise revenue to exceed $8.5 billion by 2019, Enterprise Wearables Market: 2Q 2015 Survey Results & Analysis and US Enterprise Wearables Market: 5-Year Forecast, 2014-2019. According to Compass, applications spurring growth include industrial, field services, oil and gas, healthcare, fitness and wellness-based wearable devices. These reports contain the results of a survey on wearable devices conducted online in June 2015 including insights on device and software developers, the benefits of wearables in the enterprise, and the major trends driving growth in enterprise wearables. So, what makes the enterprise fertile ground?

Wearables used in business may boost efficiency in that accessing data in a “hands free” environment can make a lot of sense. Workers can be equipped with wearable devices that can provide real-time video that can change how conditions are monitored in industrial settings. Currently, the smart phone has provided monitoring, communications, and video capabilities, but the hands-free aspect of wearables unearths a myriad of possibilities.

Yet another research report by BI Intelligence covers the dilemma of fast-moving markets—convincing consumers that wearables are beneficial, and that they need to use them now—which of course, will move the market more rapidly forward. The report delves into wearables suffering from perception problems that have put up barriers to adoption, including price, style and lack of functionality. The report forecasts that the smartwatch will be the leading wearable device category going forward.

BI estimates that the global wearables market will grow at a compound annual growth rate (CAGR) of 35 percent over the next five years, reaching 148 million units shipped annually in 2019, up from 33 million units shipped this year. BI’s report also predicts that smartwatch shipments will rise by a CAGR of 41 percent over the next five years. These smartwatches are expected to account for 59 percent of wearable device shipments this year—a number that is forecasted to expand to more than 70 percent of shipments by 2019.

PCB Industry Impact

The challenges surrounding wearables aren’t just about where to use them; they are also about how to efficiently and effectively deliver them. Wearables are having a rapid and dramatic impact on elements such as packaging, communications, performance, materials, miniaturization and process control.

Wearables, for example, depend on the ability to transmit data to a remote receiver in real time. The miniaturization of RF/wireless functionality is enabling a wide range of new applications and opening up a whole new range of applications that naturally require a smaller size, but also lighter weight, longer range and higher efficiency.

Challenges still include the introduction of parasitics at RF frequencies when an integrated packaging on PCB approach is used. Advances in materials and their electromagnetic properties are being studied to mitigate the problem. Yesterday’s portable and mobile antenna and RF techniques provide insufficient performance to wearables that require smaller geometries. Today’s solutions depend on antenna miniaturization and antenna-in-package technologies, as well as radio transceivers that shrink to match the devices that need them. Finally, 3D printing technology is rapidly gaining in importance in the production of wearable devices, as are 3D vision systems for manufacturing success.

As the wearables industry continues to explode, reaching manufacturing goals and mitigating manufacturing woes will be increasingly critical. Taking on wearable device design and development is one thing, but becoming an expert at prototype to larger device runs often isn’t compatible with the experience level of the in-house designers. An up-to-the-minute CM house with a wealth of wearable experience isn’t just a nice thing to have; nowadays, it’s needed.

Advertisement

Learn more about Advanced Assembly