Electronic design automation (EDA) is moving online, streamlining much of the design process and creating a new approach to embedded development. Known as design-to-order (D2O), these web-based tools offer an intuitive interface for developing boards quickly and easily, including supply chain operations that are integrated seamlessly behind the scenes. Makers, engineers and OEMs of all sizes have access to the same resources – which are considerably more affordable than conventional EDA platforms. Free online design tools support Linux and Android. With rapid prototyping and production, developers can have a fully designed, tested and production ready board shipped within 15 business days of order.

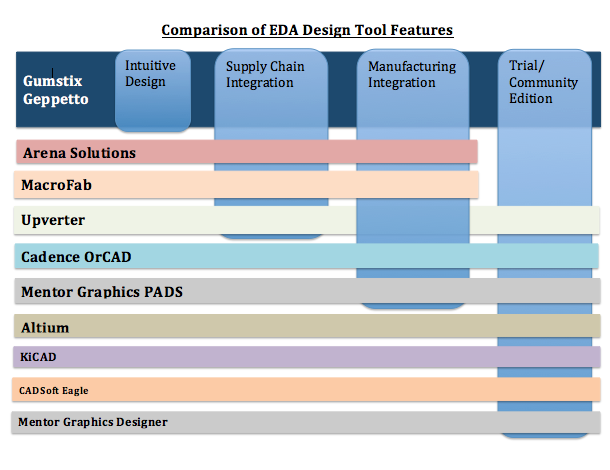

The mature EDA market offers a range of powerful products, yet they also carry a hefty price tag and require advanced tools and training. Design-to-order (D2O) tools offer an alternative, reducing risk, cost and design time by encompassing the entire development process in an intuitive web-based EDA platform.

D2O Explained

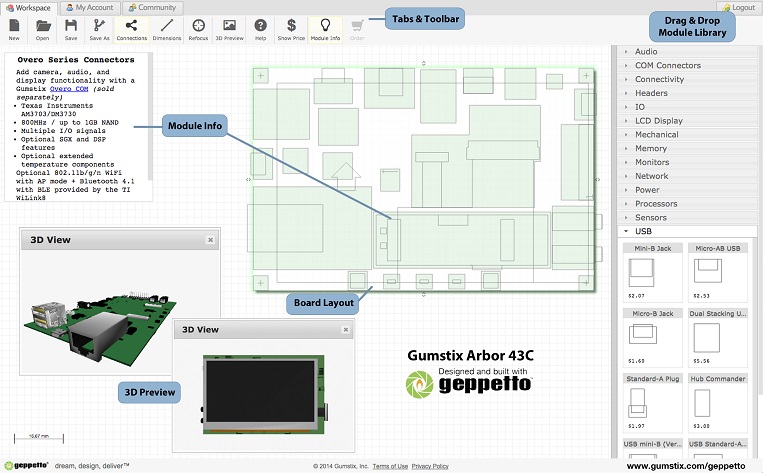

D2O creates a logical, modular design environment – enabling a drag and drop approach where ‘blocks’ or modules of functionality can be accessed and added to a design. Simple click tools allow designers to implement functions and features; elements such as connectivity or networking, or USB hubs and ports can be chosen from a field of comprehensive options. Extended details and data can be viewed or hidden with toggle controls, and the platform gives the green light when the design is complete and ready for 3D rendering and viewing. After completion, the board is ordered online and verified for proper routing. This is where D2O levels the playing field – the platform generates the schematic, layout and Bill of Materials (BoM), and ensures the board is tested for bring-up. PCB printing, component sourcing and the fabrication of the finished product is included in the D2O tool, eliminating risk and reducing manufacturing costs and timelines.

Custom Design Single or Expansion Boards for Computer-on-Modules (COMs)

Gumstix’ Geppetto® D2O tool illustrates the process; developers can either design a board from the ground up or build a custom expansion board utilizing an existing Gumstix COM, or newly supported BeagleBone Black COM Connector for the exact needs of their end-use application. Designers can create custom expansion boards accessing drag and drop options such as TI’s WiLink™ 8 combo-connectivity module (Wi-Fi® + Bluetooth®). Once design is complete online, a market-ready device can be ordered from the same D2O platform and shipped in approximately 15 business days. Total cost of ownership is based on a setup and manufacturing fee of less than $2K plus component costs, as opposed to the $20K-$40K investment required for conventional EDA applications

Gumstix’ Geppetto design-to-order (D2O) tool offers an alternative, to existing EDA solutions reducing risk, cost and design time by encompassing the entire development process in an intuitive web-based EDA platform. Inclusion of 3rd party COMs such as BeagleBone Black, “Raspberry Pi Compute Module” and DragonBoard TM broadens D2O support of the industrial Internet of Things and DIY market, providing serious makers with the same rapid and automated production path to commercial and industrial markets, accessible to embedded developers worldwide.

D2O and BeagleBone Black

In a BeagleBone Black example, several capes, or expansion boards, may need to be added to the base board to obtain all the desired functionality required for a device. Tools such as Geppetto allow designers to reduce the number and size of capes by combining multiple functional blocks onto a single custom cape. A single custom cape – rendered in 3D prior to ordering – could include a USB Console port, GPS connector, LCD Display, WiFi and Bluetooth. Overall, custom hardware development is kept simple and streamlined, even while the platform ensures maximum compatibility with OEM software.

Moving Beyond Design and Into the Supply Chain

D2O blends more design processes into a streamlined, user-friendly system. Costly steps between design and production are eliminated, ensuring that custom device development is a quick and cost-effective process that allows designers and OEMs to focus on how to distinguish their software instead of wasting resources on board layouts. By combining functions in a logical web-based interface, risk and total cost of ownership is reduced – capitalizing on operating system support, supply chain management and out-of-the box functionality for the developer.

The Geppetto® automated manufacturing cycle completes the PCB routing, fabrication, sourcing, component purchasing, assembly and board bring up. Automation of the supply chain reduces engineering and manufacturing time and cost. Custom expansion boards can be designed in a few hours, ordered, tested and shipped production ready within 15 days.

Optimized D2O platforms include a diverse 100-plus module library, as well as integrated supply chain features that demonstrate how each module affects the bottom line. For large-scale development of thousands of boards, or individual or one-off maker projects that are used for quick prototyping, it’s a smart approach that encompasses the entire process of design, supply chain integration and manufacturing automation.

Author

Andrew Simpson, technical writer, Gumstix

Advertisement

Learn more about Gumstix