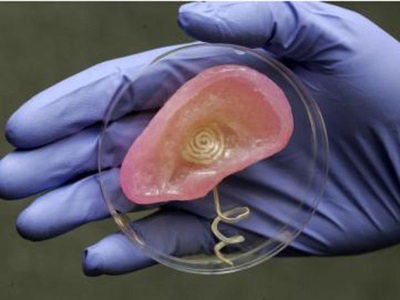

3D printing spent many years as a niche technology for rapid prototyping, and now suddenly it has emerged as manufacturing technology with a thousand uses spread across a very diverse user base. Possible and actual users of 3D printers now include everyone from hobbyists to dentists to jewelers to giant aerospace firms. For example, being able to print a complex parts for a vacuum cleaner that enhances the design of the product, while also eliminating couple extra assembly steps. From this perspective, the 3D printer is just another tool in the workshop. These efficiency gains will help their perspective industries, even if they aren’t revolutionizing the world. But what manufacturers are really interested in is finding the next big thing.

Entrepreneurs are searching for ways to employ 3D technology to hit a homerun. Consumer goods may be the best place to do that. By creating a new product category or improving an existing category so much that it essentially creates a new product category, and that entrepreneurs could potentially capture huge rewards. Successful manufacturers will instead seek to employ 3D printing in niches of larger product categories, creating products that appeal to consumers.

SmarTech’s report “Low-volume manufacturing: Mass customization markets for the 3D printing industry – 2013 to 2022 ” says these trends are creating an immediate opportunity in the materials space. Each user group and each application needs its own materials set but most use ABS, PLA plastics and some metals.

Change in the 3D printing materials sector is now occurring at multiple levels. New materials such as novel alloys and even concrete are started to be printed. And it is becoming clear that the roads to success in the 3D printing materials sector will depend on finely tuning materials offerings to the needs of each application. This fine-tuning process will involve not just the type of material itself, but also material quality, and the selection of marketing channels and packaging.

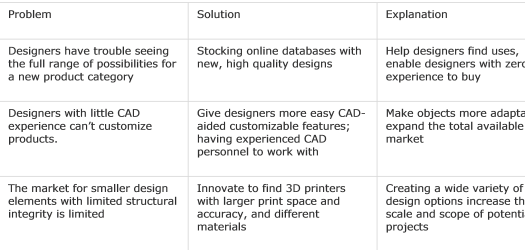

The success of 3D printing in the design industry hinges on three things, shown in the table below:

Critical Factors For 3D Printing’s Success In Design Elements

As you can see from the table, the online service bureaus that can make the customization process better and easier will win market share. Online 3D printing service provider must make sure to stock their online market places with high quality designs. This may entail employing CAD designers to stock the market place or providing proper monetary incentives for designers to populate the marketplace with products, rather than relying on “makers” to populate the marketplace themselves. The ten-year forecast provides an appraisal of the strategies of the key firms influencing this market. For more information visit, http://www.smartechpublishing.com/low-volume-manufacturing-mass-customization-markets-for-the-3d-printing-industry-2013-to-2022-10-2013.html

Advertisement