BY EDUARDO ESPARZA

Product Marketing Engineer, Embedded Processors

Texas Instruments Inc.

www.ti.com

Every controlled electrical or mechanical machine has a human-machine interface (HMI) in the form of a pushbutton, lever, or touchscreen. At a high level, an HMI has three basic elements: input, output, and something to handle the translation between the two.

As we move into the Industry 4.0 era, this model gets a little more complex. Designers are adding graphical user interfaces (GUIs), moving from physical buttons to virtual buttons on the GUI, increasing the number of tasks the HMI can perform, and even displaying performance feedback in a closed-loop system.

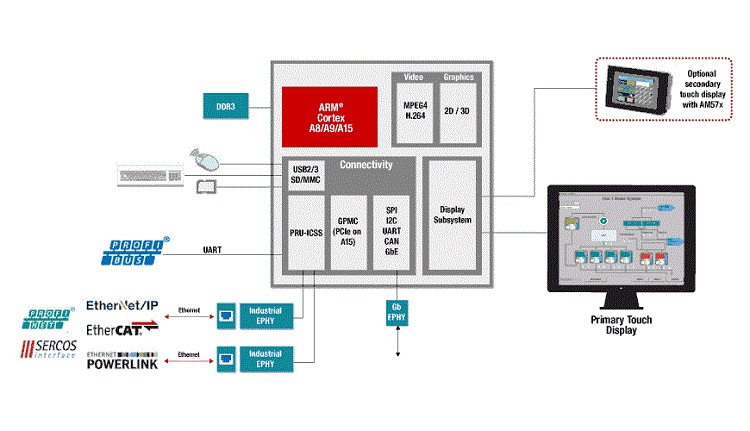

Fig. 1: An embedded processor is at the heart of the modern-day industrial HMI.

General HMI processor requirements

An HMI can have many requirements for an embedded processor, depending on its intended end application. There are four levels of HMI performance: entry level, basic, mid-end, and high-end.

An entry-level HMI has a very basic user interface. The output screen is usually quarter video graphics array (QVGA), 320 x 240 at best, and has minimal 2D graphics. These HMIs are geared toward cost-sensitive applications that require only the bare essentials of a control interface. Designers may use a resistive touchscreen here because it’s more economical than its capacitive-touch counterpart.

Not only is the resistive touchscreen more inexpensive than a capacitive touchscreen, the BOM cost may also be lower because some processors can natively support resistive touchscreens while capacitive touch sometimes requires external components. This category of HMI is best for a low-performance processor (

Basic HMIs add improved display resolutions and a slightly better user interface than entry-level HMIs. A basic HMI will have a touchscreen — usually resistive touch — and up to extended graphics array (XGA) (1,024 x 768) display resolution to improve the user experience. Depending on the required application processing power, a processor for this category would be in the low- to mid-end performance range (300 MHz to 800 MHz) and may benefit from a 2D graphics accelerator.

Fig. 2: Choosing the right processor for HMI requires careful design consideration.

A mid-end HMI more closely reflects a typical GUI that a user might interact with on a daily basis. Mid-end HMIs have 2D graphics, display resolutions up to XGA (1,024 x 768), incorporate more control functionalities than the basic category, and sometimes even introduce haptic or audible feedback. These features greatly improve the user experience. For a mid-end HMI, the processor has to include graphics acceleration, mid-range performance (600 MHz to 1 GHz), and graphics libraries to help build the GUI.

High-end HMIs are naturally multimedia-rich. They require a high-end SoC with high-definition video support, 2D and 3D graphics accelerators, and high-performance processors (multicore and >1 GHz). And this can greatly benefit from on-chip DSPs to help accelerate audio and video processing. Additionally, high-end HMIs usually require a processor that can handle multiple high-resolution screen outputs and HTML5. One example is the Sitara processor family based on Arm Cortex-A cores, which provides the scalability needed to develop a single platform ranging from entry-level to high-end HMI and supports industrial reliability.

You can find HMIs in household appliances, vending machines, building automation systems such as fire control panels or elevators, and electric vehicle charging stations. However, one of the most prevalent uses of industrial HMIs is in the factory automation space.

HMIs in factory automation systems

In factory automation systems, an HMI connects the machine’s operator to a controlling function, typically a programmable logic controller (PLC), which controls the sensors, actuators, and machines on the factory floor. HMIs are also more commonly included on machines and robots themselves and, in some cases, manage some of the control function within the HMI. These applications create a number of requirements for a processor in the HMI, including the need for industrial communication capabilities, industrial-grade reliability, and security features.

Industrial communications

Standard Ethernet doesn’t have the deterministic functionality required for industrial automation. And that’s where protocols designed for industrial communication come into play. Industrial Ethernet protocols achieve the real-time, deterministic communication needed between different types of end equipment in a control system.

There are currently over a dozen different protocols created for industrial Ethernet. A processor, FPGA, or ASIC is required to handle these protocols in an HMI. In many cases, an HMI will have a host processor and a separate ASIC or FPGA to run a single protocol.

As an alternative to the FPGA or ASIC, integrated solutions exist that can serve as both the application processor and communications engine for industrial Ethernet; these solutions may even extend functionality to support multiple protocols.

Multi-protocol support in an HMI adds a much-needed level of flexibility for Industry 4.0 because control systems in a smart factory are often pieced together from different solutions running different protocols. With multi-protocol support, an HMI can act as a gateway between different protocols.

Industrial-grade quality

Factories operate 24/7 year-round in most cases. And conditions can vary from sub-freezing to boiling-hot temperatures, depending on what the factory is producing. An HMI inside a factory must be able to withstand these conditions, and so must the processor inside it. It brings up the need for industrial-grade processors in factory automation HMIs.

Fig. 3: HMI requirements significantly increase in factory automation.

An industrial-grade processor must be able to withstand a wide range of temperatures, typically –40°C to 105°C. Additionally, because factory equipment operates for long periods of time, extensive device longevity testing is required. One metric used for a device’s longevity is its power-on hours (POH), which is the number of hours that it can be powered and operate properly. A processor with a wide temperature range and POH exceeding 88,000 would essentially be able to run for over 10 years. Most industrial HMIs are required to meet at least 100,000 POH.

Security

Although the HMI and the rest of the control network are usually configured on an internal Ethernet network isolated from the main internet, there still exists the possibility of a malicious party eavesdropping or altering communications between the HMI and other parts of the system. To help deter unwanted interference, embedded processors often integrate cryptographic accelerators to encrypt data. Secure boot is another popular security option available to help protect an HMI manufacturer’s intellectual property.

Other HMI aspects

Because an HMI is primarily a user interface, it requires the use of a high-level operating system (OS). Popular OSes for HMI include Windows CE, Android, and Linux. Windows CE has been popular in HMIs for many years, especially in factory automation, but Android and Linux are gaining traction for a couple of reasons.

First, Android and Linux are open-source OSes, which means that they can be free to implement. Additionally, because they are open-source, there is a large community supporting software and providing example code for each OS.

Android is popular in systems in which a large variety of users will interact with the HMI, such as in a vending machine or appliance. Android is already popular in the handheld device market, so the learning curve for someone new to the HMI is minimized because they may already be familiar with the OS.

In factory automation, Linux has become the likely choice because it is widely considered to be stable, reliable, and secure. Many industrial HMIs don’t require all of the features that come with Android. On the other hand, Linux also supports frameworks like Qt and the Open Graphics Library (OpenGL), which help build an effective GUI.

Another feature that is gaining popularity in HMI is virtualization. As previously mentioned, HMIs are popularly integrated with other end equipment such as PLCs, industrial robots, and CNC machines. One method of integration would be to have separate processors for the HMI and other application, but this can be costly and require additional board space.

The alternative method is to have a single, multi-core processor with a core dedicated to the HMI and another core dedicated to the application. The cores can run different OSes such as an RTOS and Linux, depending on whether a real-time operation is needed.

Summary

HMIs cover a broad array of end applications at a wide range of performance levels but share a few common features, including GUIs, connection to the control system, and touch-based controls. At the bare minimum, a processor must be able to support these entry-level HMI requirements. These features can be taken further by basic, mid-end, and high-end HMIs to include HD graphics, web browsing, video, and multiple-screen support.

Advertisement

Learn more about Texas Instruments