Scientists at Lawrence Livermore National Laboratory have discovered that by treating the electrodes on a lithium-ion battery with a bit of hydrogen, the rechargeable power source lasts longer and operates faster.

The way in which these batteries operate is pretty simple — lithium ions move from the negative electrode to the positive electrode during discharge, and back when charging. Things like the battery’s capacity, voltage, and energy density are all determined by the binding between the lithium ions and the electrode material. Changes in the structure, chemistry, and / or shape of these electrodes can wind up affecting how strongly lithium ions bond to them which, in turn, affects the charge / discharge rate of the battery itself.

Various experimentations and calculations were performed before the team arrived at the solution that hydrogen-treated graphene nanofoam electrodes in the lithium ion batteries show higher capacity and faster transport than the standard alternative.

“These findings provide qualitative insights in helping the design of graphene-based materials for high-power electrodes,” said Morris Wang, a materials scientist at the Lab, and co-author of the paper describing the solution.

Diving into the technical details a bit deeper, the team’s experiments and calculations revealed that deliberate low-temperature treatment of defect-rich graphene with hydrogen can improve rate capacity. This is because hydrogen interacts with the defects in the graphene, opening small gaps that wind up allowing for easier lithium penetration.

Additional reversible capacity is provided by enhanced lithium binding near edges, as this is where hydrogen typically binds.

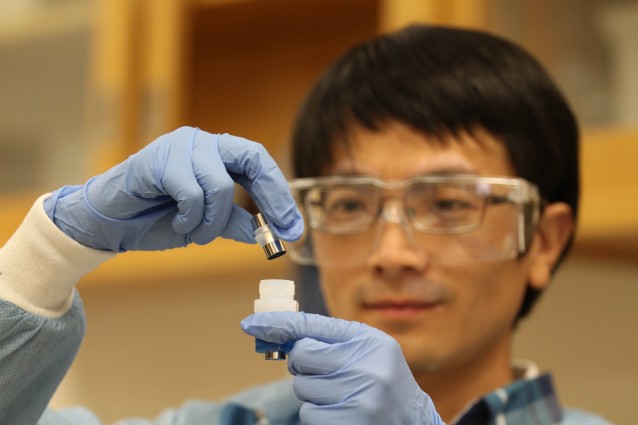

“The performance improvement we've seen in the electrodes is a breakthrough that has real world applications,” said Jianchao Ye, who is a postdoc staff scientist at the Lab's Materials Science Division, and the lead author of the paper.

In order to test the involvement of hydrogen and hydrogenated defects in the lithium storage ability of graphene, the team used various heat treatment conditions combined with hydrogen exposure, and looked into the electrochemical performance of 3D graphene nanofoam electrodes. Particularly attractive about this type of electrode is the binder-free nature of the graphene nanofoam, which makes it perfect for use when it comes to mechanistic studies — they can be used without having to worry about the complications that come with using additives.

“We found a drastically improved rate capacity in graphene nanofoam electrodes after hydrogen treatment,” said LLNL scientist Brandon Wood, who directed the theory effort on the paper. “By combining the experimental results with detailed simulations, we were able to trace the improvements to subtle interactions between defects and dissociated hydrogen. This results in some small changes to the graphene chemistry and morphology that turn out to have a surprisingly huge effect on performance.”

Also worth pointing out about 3D graphene nanofoam: it’s incredibly versatile. Applications to which it can be applied include hydrogen storage, catalysis, filtration, insulation, energy sorbents, capacitive desalination, supercapacitors, and of course, lithium ion batteries. So, a discovery using this material would benefit not just one technology, but as Ye suggested above, several real world applications.

To learn more, download the team’s paper, which was published in Nature Scientific Reports, under the title “Universal roles of hydrogen in electrochemical performance of graphene: high rate capacity and atomistic origins.”

Advertisement

Learn more about Electronic Products Magazine