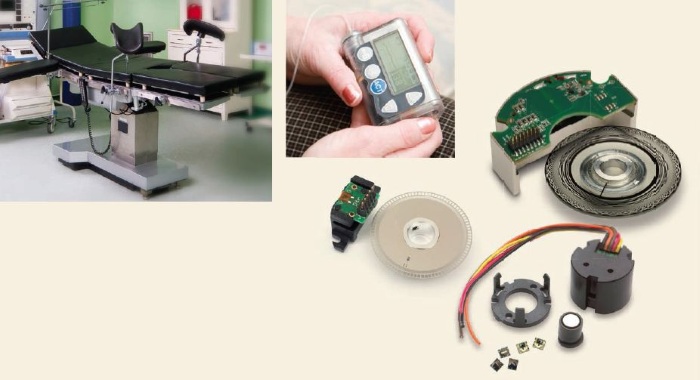

Today’s medical equipment is often tasked with performing incredibly complex, highly sensitive procedures that require the utmost levels of precision and attention to detail.

Technologies like motion control encoders are used in conjunction with this equipment, ranging from life support systems to the robotic arms attached to operating tables. They empower the medical professional with the information necessary to make informed decisions throughout the treatment, and ensure that each procedure performed is a successful one.

Obviously, this is a fairly intricate piece of technology, and so there are few manufacturers with the means to actually produce it. One company that does offer motion control encoders to medical equipment designers is Avago Technologies.

Avago has a broad portfolio of motion control encoders, including incremental, absolute, and rotary type. For those unfamiliar, incremental encoders provide relative positional data referenced to a known start position. An absolute encoder, on the other hand, provides absolute positional data with no reference to another position.

Both encoders are able to sense the mechanical motion of the equipment in use and translate information about it, including its position, velocity, and acceleration, into useful digital data for the medical professional to review and make their decisions.

Rotary encoders, or “shaft encoders,” are responsible for converting the angular position or motion of a shaft or axle into useful digital data.

If you want to learn more about this detail, here’s a further breakdown of the three types of motion control encoders that Avago has to offer, along with links to the products themselves:

Incremental Encoders: Avago’s incremental encoder solutions include a wide selection of optically transmissive and reflective encoders, all of which are available in various chip modules and plastic housings. Key features about these incremental encoders include high resolution, minimal switching glitch, and small form factor.

• Incremental Encoders and Code Wheels (19 available)

• Reflective Encoders (43)

• Transmissive Encoders (330)

Absolute Encoders: Avago’s absolute encoder solutions include optically transmissive and magnetic encoders. These products are available in various chips, modules, and plastic housings.

• Multi Turn Encoders (2)

• Single Turn Encoders (3)

Rotary Encoders: Avago’s rotary encoder solutions include an extensive selection of housed rotary switches that can be used for human-machine interface for rotary control or data entry. Rotary resolution options range from 50 to 3,600 counts per resolution (CPR) for incremental and 17-bit single-turn absolute.

• Rotary encoders (66)

Also available via Avago are encoder accessories, including a wide variety of cables and alignment tools, which can provide medical equipment designers with a complete encoder solution, thereby making it far easier to assemble the encoders into the end applications.

To learn more about Avago’s motion control encoder solutions, visit avagotech.com/encoders

Advertisement

Learn more about Avago Technologies