By Alix Paultre, contributing editor

Power is ubiquitous, and there is no electronic system that can work without electricity. That means that power transmission is as important as power conversion, and it should be considered two sides of the same system. Any inefficiencies or losses in moving the power from Point A to Point B will render moot any advances or efficiencies in power electronics.

That’s why the right connectors and cables are critical, as they play a direct role in any product’s safe and effective operation. But what happens when the cables are no longer needed, at least for the “final foot” from the product’s external power supply to the internal electronics? This is especially important for battery-driven systems, which need to be regularly recharged by plugging it into the wall. Eliminating that charging cable opens up a world of benefits and challenges.

Freedom!

At the product level, wireless charging is creating a new level of freedom in devices at almost every level. Eliminating the power port brings advantages to the packaging, board layout, and bill of materials (BOM) to manufacturers. The ability to charge a device by simply placing it on a surface also empowers designers of aftermarket devices, from cars to furniture, to create charging surfaces in their products to expand their market to include smart devices.

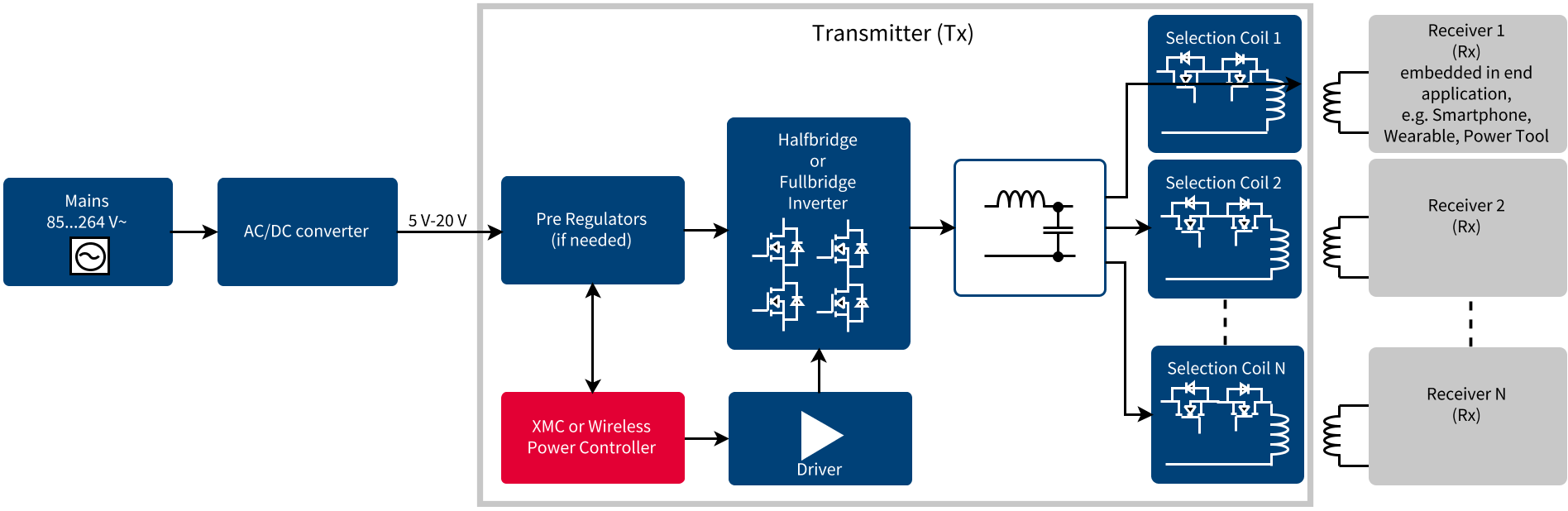

Currently, there are two standards in wireless charging. The Qi protocol, an open-interface standard developed by the Wireless Power Consortium, is an inductive wireless charging system for single- and multi-coil topologies. Occupying the bandwidth from 110 kHz to 205 kHz, Qi is currently the market leader (Fig. 1 ). Its widespread use can be attributed to its cost-efficiency. Inductive topologies must use in-band communication.

Fig. 1: The Qi protocol is an inductive wireless charging system for single- and multi-coil topologies. (Image: Infineon)

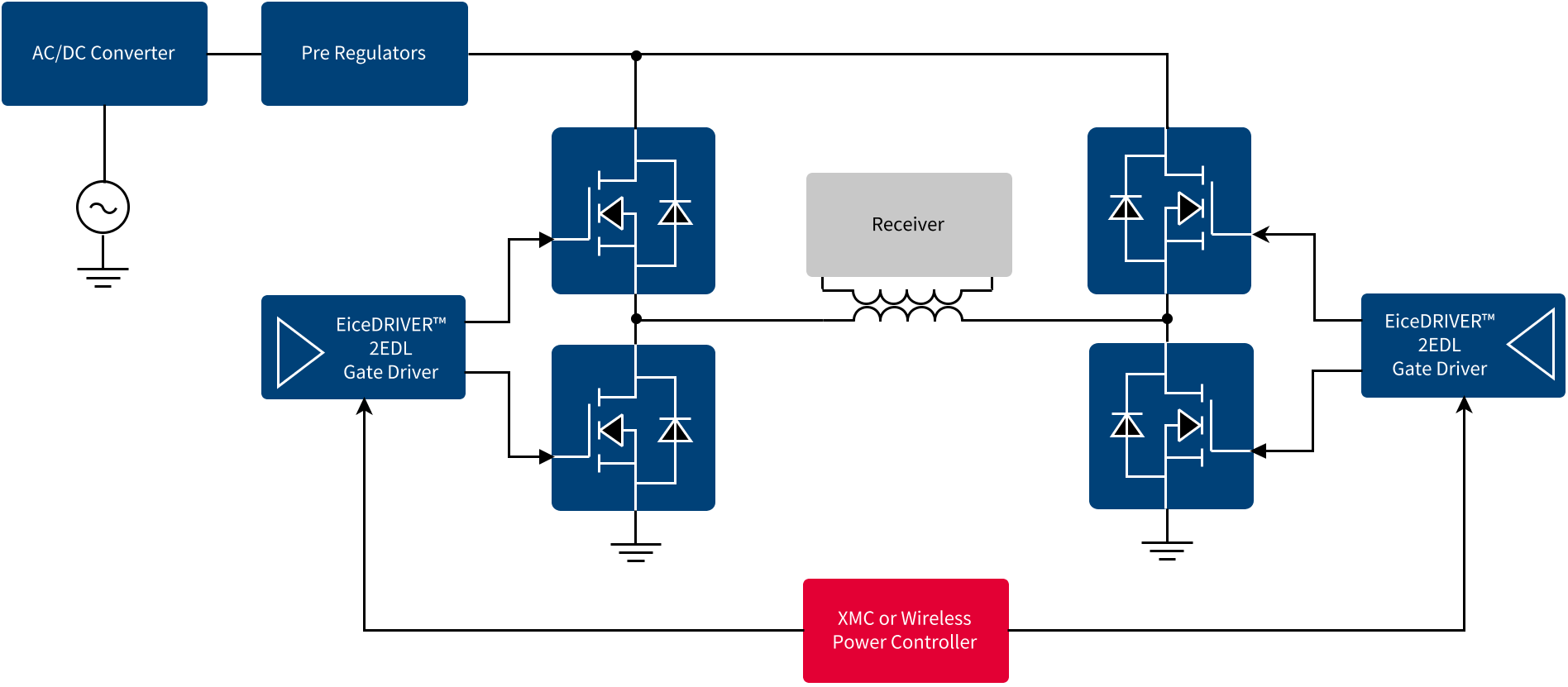

AirFuel, a resonant technology operating at 6.78 MHz, was developed by the AirFuel Alliance standards organization. Advantages that AirFuel has over Qi include a wider position and distance acceptance range and the ability to charge multiple different devices in parallel. Another advantage is that AirFuel devices communicate using Bluetooth Low Energy. Fig. 2 shows a Class D (full-bridge or half-bridge) amplifier layout. You can also create a Class E (single-ended or differential) amplifier design to suit your application.

Fig. 2: AirFuel is a resonant technology that operates at 6.78 MHz. (Image: Infineon)

Fig. 2: AirFuel is a resonant technology that operates at 6.78 MHz. (Image: Infineon)

Although wireless charging can take place over relatively large (nodding toward inverse-square rules) air gaps, most consumer devices will use wireless charging functionality as a cable eliminator. The application most sensitive to the air gap is automotive, as charging and receiver coils will be separated by the vehicle’s ground clearance unless there is some kind of spacer to close the gap as much as possible to maximize energy transfer.

Eliminating the last few feet of cable also removes tons of wires and their eventually obsolete connectors from the earth, as the cables get discarded when the connector technology gets superseded by the next generation of functionality. Properly implemented, wireless charging systems will become a more permanent power infrastructure that can support multiple generations of successive technology.

In addition, once you make power wireless, it becomes part of the device’s I/O on the software side as well. This not only means the necessary intelligence to manage the wireless power transfer but also the ability to send data over that link. This gives designers the ability to add additional functionality to their products for things like security and verification.

Every engineer knows that any functionality added to a device also add layers of complexity. With wireless charging, the power system becomes a part of the device’s logic, so it can be used as an avenue of hacker attack on the host system, for example. Security is one of the most important aspects of wireless power systems because they provide a communications back door into your product. Your power management system now needs a firewall and authentication to properly operate in a wireless environment.

Safety didn’t go anywhere in the meantime, so that means that all aspects of the wireless system must be safe and reliable. This means paying attention to thermal management and other issues related to incorporating new technology into “old” applications. An example is thermal considerations in a sealed system such as furniture with charging plates built into its surfaces.

Putting it together

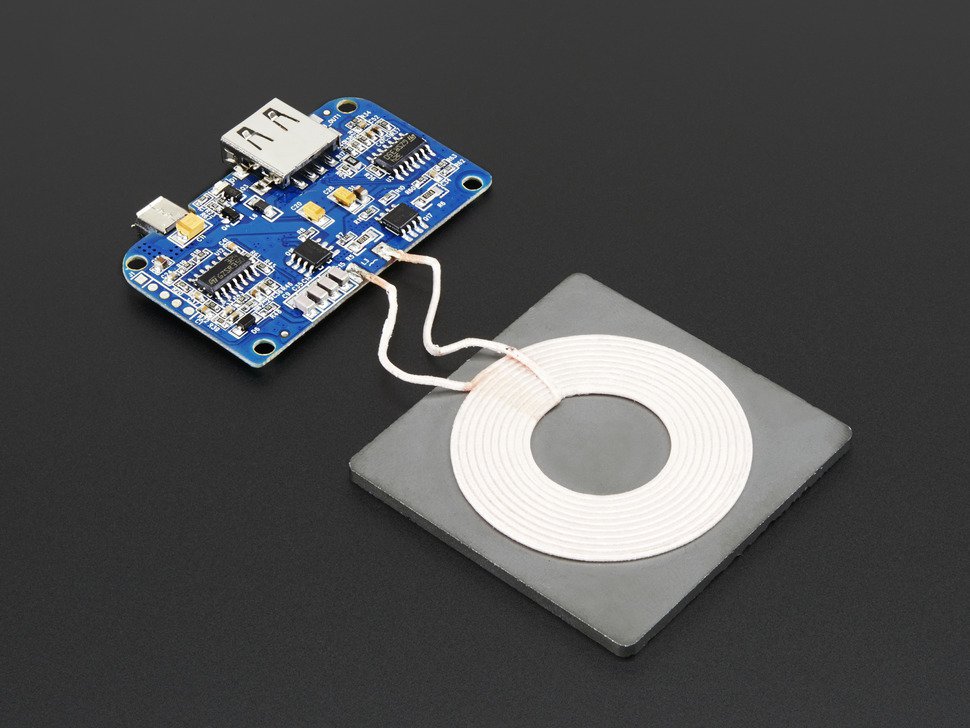

A wireless charging system needs three primary components (on each end): a controller, a power circuit, and the coil for transmission and reception. There are many ways to create a wireless charging system, and most vendors not only carry the components required, many have full-blown reference designs, development kits, and even full systems to make it significantly easier (Fig. 3 ). Of course, as with anything, a custom design made from properly selected components has the best chance of providing the best solution.

Fig. 3: Most vendors now offer wireless power development kits or complete systems. (Image: Adafruit)

Fig. 3: Most vendors now offer wireless power development kits or complete systems. (Image: Adafruit)

For example, Texas Instruments’ bq51051B is a Qi-compliant receiver chip targeting portable and IoT apps and integrates the digital controller needed for Qi v1.1 communication. Able to manage both Li-ion and lithium-polymer battery charging, the receiver chip and its matching bq500212A transmitter-side controller create the heart of a complete wireless power system for direct battery charger solutions.

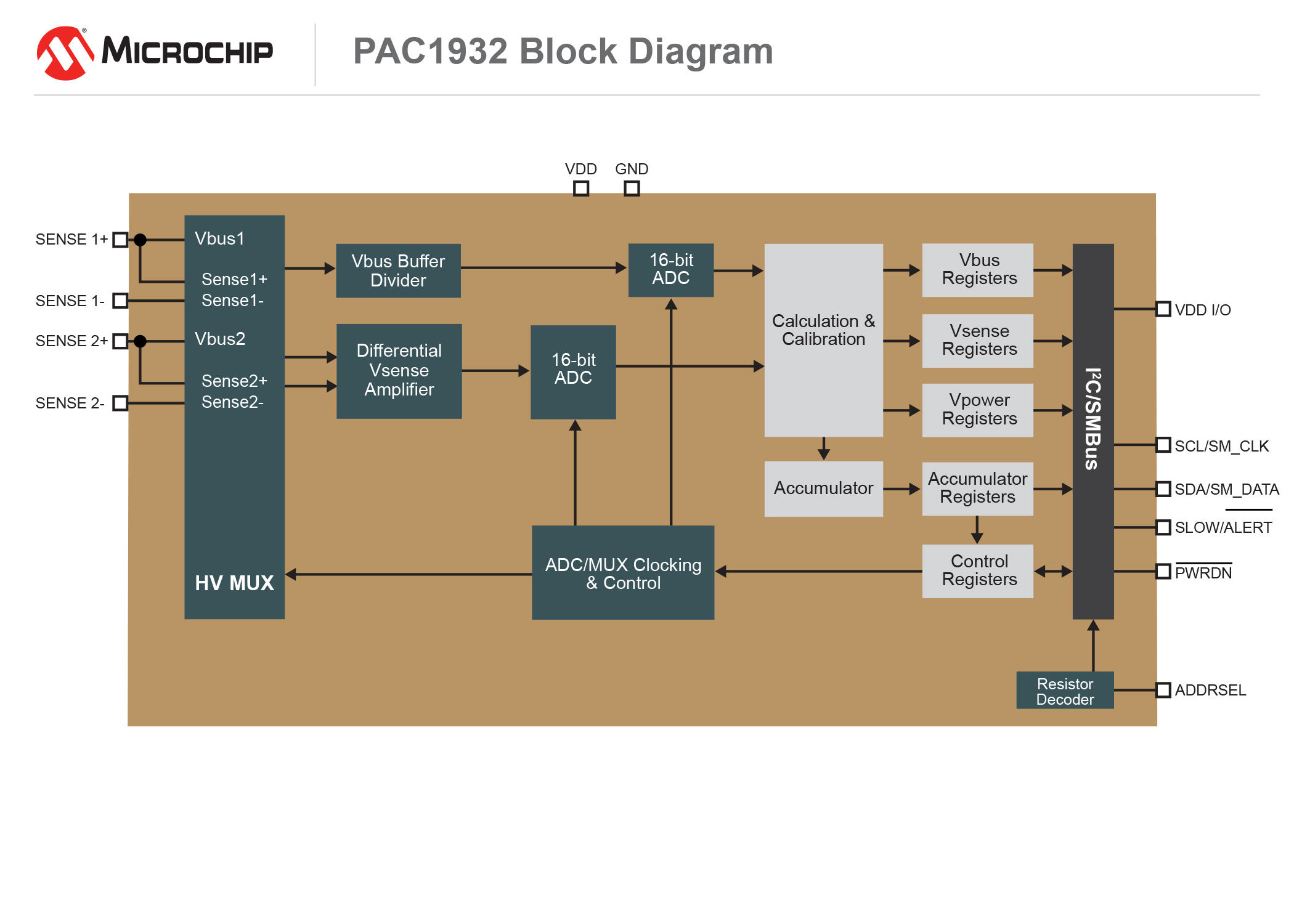

Of course, the more accurate your monitoring, the better the performance of the system, especially in wireless power, where there are already multiple places where inefficiency can occur. One solution is to use a device like Microchip Technology Inc.’s PAC1932, a dual power and energy monitor that reports on bus and sense voltage with 16 bits of resolution (Fig. 4 ). Power is reported as a simultaneous product of two 16-bit independent bus and sense voltages. All registers are accessible through an I2 C/SMBus interface including an eight-sample average for reading stability. Fig. 4: Microchip’s PAC1932/3/4 are two-, three-, and four-channel power and energy monitoring devices. A high-voltage multiplexer sequentially connects the inputs to a bus voltage monitor and current sense amplifier that feed high-resolution ADCs. (Image: Microchip Technology)

Fig. 4: Microchip’s PAC1932/3/4 are two-, three-, and four-channel power and energy monitoring devices. A high-voltage multiplexer sequentially connects the inputs to a bus voltage monitor and current sense amplifier that feed high-resolution ADCs. (Image: Microchip Technology)

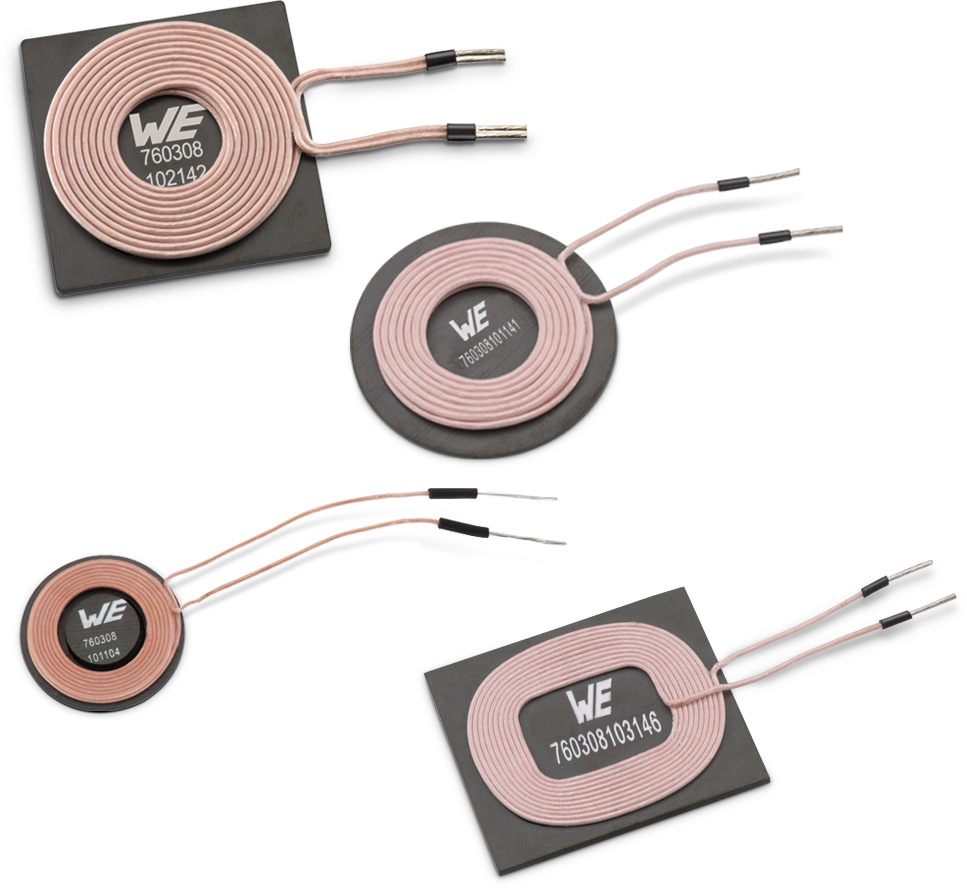

The ability to choose exactly the antenna needed is also important, as antenna mismatching will cause inefficient operation (Fig. 5 ). Other important features in an antenna include the type of wire used, power level achievable, how well-shielded it is, how well-constructed it is (proper core construction limits the stray field in the design), and even how it connects to your board.

Fig. 5: The ability to choose exactly the antenna needed is also important. (Image: Wuerth)

Fig. 5: The ability to choose exactly the antenna needed is also important. (Image: Wuerth)

Development kits also give designers the ability to evaluate a company’s solution. In addition, kits provide a jumping-off point to modify and customize appropriately for your application. For example, an evaluation kit for a 15-W, Qi-compliant, end-to-end wireless charging solution based on the STMicroelectronics STWBC-EP/STWLC33 chipset is optimized for Extended Power Profile (EPP) Wireless Power Consortium (WPC) Qi 1.2-certified applications up to 15 W. The STWBC-EP digital controller for wireless charger transmitters enables half- or full-bridge topologies as well as single- and multiple-coil designs.

Another thing to remember about wireless power is that it needs software and coding. This development kit comes with the associated STWBC-EP firmware (STSW-ISB044FW) and a graphical user interface (STSW-STWBCGUI) to help with debugging and configuration. A firmware downloader tool (STSW-STWBCFWDT) is also available. There is no such thing as too much software support.

STMicro also offers the STEVAL-ISB045V1 wireless battery charger dev kit that can create chargers for wearables and the IoT and includes software, documentation, and hardware. Able to make small wireless chargers up to 2.5 W, the solution has a 20-mm coil for charging small devices such as smartwatches and other small devices.

Usable as a turnkey solution or customized for specific apps, the STWBC-WA supports all common wireless charging features, including active presence and foreign-object detection.

Looking forward

Wireless charging is about to revolutionize portable devices by freeing them from cords completely. Proper design of your wireless power solution will make the difference between product success and failure in this highly competitive marketplace.

Advertisement

Learn more about Electronic Products Magazine