By Gina Roos, editor-in-chief

The electric vehicle (EV) industry has been looking for a rechargeable battery that can deliver hundreds of miles on a single charge, leading researchers to seek a replacement for graphite anodes currently used in EV batteries with lithium metal anodes. Researchers at the Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab), and Carnegie Mellon University, reported a potentially gaming-changing solution – a new class of soft, solid electrolytes that are made from polymers and ceramics that suppress the formation of dendrites in lithium metal anodes that can cause battery failure.

While lithium metal extends an EV’s driving range by 30% to 50%, said researchers, the technology forms lithium dendrites, described as tiny treelike defects, on the lithium anode during charge and discharge cycles that shorten the battery’s life. They also can short circuit the battery cells if in contact with the cathode.

Researchers reported in the journal Nature Materials that the new class of soft, solid electrolytes suppress dendrites in the early nucleation stage before they can grow and cause the battery to fail.

Instead of assuming that hard, solid electrolytes like ceramics work best to prevent dendrites, as thought for decades, researchers took a soft, solid electrolyte approach to the problem. Key to the design, said researchers, is the use of soft polymers of intrinsic microporosity, or PIMs.

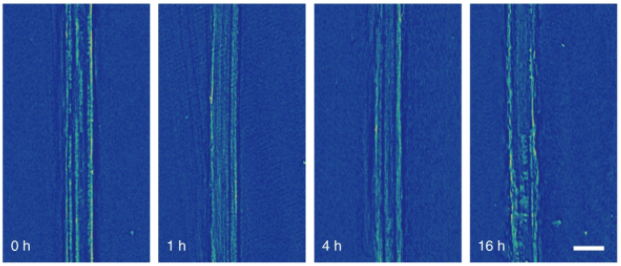

To demonstrate that the new PIM composite electrolyte suppresses the formation of dendrites, researchers used X-rays at Berkeley Lab’s Advanced Light Source to create 3D images of the interface between the lithium metal and the electrolyte, and to visualize lithium plating and stripping for up to 16 hours at high current. The demonstration indicated continuously smooth growth of lithium with the new PIM.

3D images of the interface between lithium metal and the electrolyte. (Image: Brett Helms/Berkeley Lab)

In addition, solid-state storage technologies, like lithium metal batteries, though providing high energy density and safety, also have materials and processing challenges.

Researchers said the new flexible solid battery can be manufactured into rolls of lithium foils with the electrolyte as a laminate between the anode and the battery separator. Called lithium-electrode sub-assemblies, or LESAs, they can be used as drop-in replacements for traditional graphite anodes, which allows battery manufacturers to use their existing assembly lines.

“Our dendrite-suppressing technology has exciting implications for the battery industry,” said Brett Helms, a staff scientist in Berkeley Lab’s Molecular Foundry , and co-author of the paper, in a statement. “With it, battery manufacturers can produce safer lithium metal batteries with both high energy density and a long cycle life.”

Helms also noted that lithium metal batteries manufactured with the new electrolyte could be used to power electric aircraft. Under the Advanced Research Projects Agency-Energy’s (ARPA-E) IONICS program, 24M Technologies has integrated these materials into batteries for EVs and electric vertical takeoff and landing aircraft (eVTOL).

Advertisement

Learn more about Electronic Products Magazine