By Majeed Ahmad, contributing writer

Motion sensing is a key ingredient in the portable designs built around augmented reality (AR) and virtual reality (VR) applications. But while motion sensors are bridging the real and virtual worlds, a more specialized device, the inertial measurement unit (IMU), is ideally suited to serve the nascent AR/VR markets.

AR/VR applications are now a key battleground for smartphones as well as wearable devices such as smart glasses and head-mounted displays (HMDs). At the same time, however, AR/VR designs demand highly sensitive, precise, robust and responsive motion sensors.

AR superimposes audio, graphics, and other sense enhancements in real time. (Image: STMicroelectronics)

Here, the IMU, a combination of an accelerometer and a gyroscope, provides the accuracy of fast-motion measurements and the granularity of slow-motion measurements. So smartphone and wearable designs can create a more authentic and immersive AR and VR experience for users and engage them with real and virtual environments for longer periods without requiring frequent breaks.

This article will provide a detailed treatment of how IMUs facilitate a much more realistic and pleasant experience in the exciting worlds of augmented and virtual reality. Besides application-suitability needs, it will also delve into the latest IMU design enhancements like the integration of processing cores and improved image stabilization aiming to bolster AR/VR designs.

Anatomy of an IMU

IMUs ensure stability in environments with high motion fluctuations often encountered in HMDs and AR gizmos like smart glasses. It begins with accuracy, a critical requirement in the lightning-fast high-definition AR/VR applications.

The ultra-precise and instantaneous detection of head movements, for example, reduces the time lag to an almost imperceptible minimum. That, in turn, reduces motion-sickness effects like nausea. The negative physical effects can also be mitigated with a low-noise accelerometer and low-drift gyroscope.

For example, in the BMI085 , Bosch Sensortec’s six-axis IMU, the accelerometer ensures temperature stability with a low temperature coefficient offset (TCO) of typically less than 0.2 mg/K and temperature coefficient sensitivity (TCS) of 0.002 %/K. In addition, it achieves a noise density of under 120 μg/√Hz.

According to Bosch Sensortec, the IMU’s accuracy is further boosted by data synchronization of the accelerometer and gyroscope.

The gyroscope in the BMI085 features a closed-loop analog-to-digital conversion mechanism, which ensures low-drift characteristics even in high-fluctuation temperature environments. And the bias instability of the gyroscope is typically below 2°/h.

The low-noise accelerometer combined with the low-drift gyroscope enables the IMU to deliver a low motion-to-photon latency of less than 3 ms. The exceptionally low latency helps design engineers eliminate image drifts and offers a genuinely real-life experience.

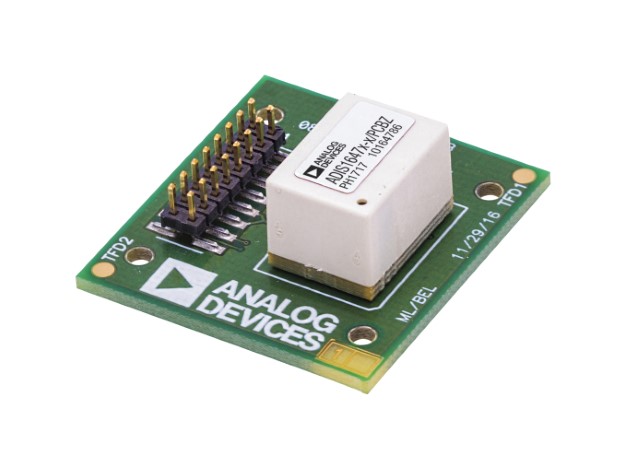

Another IMU claiming to characterize motion sensing accurately despite turbulence, vibration, wind, temperature, and other environmental disturbances is the ADIS16475 from Analog Devices Inc. The ADIS16475 motion sensor — combining a three-axis accelerometer with a three-axis gyroscope — is targeted at autonomous machine applications.

The ADIS16475 inertial sensor features motion testing and calibration as part of the production process to reduce system-integration overhead. (Image: Analog Devices)

ADI claims that its miniature MEMS sensor also features signal conditioning to optimize dynamic performance. This dynamic compensation allows ADIS16475 to provide accurate sensor measurements over a broad set of conditions. Additionally, it eliminates significant error sources originating from cross-axis sensitivity, temperature, and mechanical stress-related drifts.

IMU’s local processing

Another notable development in IMU designs is the integration of logic into motion sensors so that they can process the gesture detection and recognition algorithms inside the IMU. First and foremost, that relieves the main MCU or MPU from complex motion-processing tasks such as activity recognition and context awareness. Secondly, compared to using an external MCU, it consumes a fraction of the power to run the algorithms for motion and gesture detection.

IMU suppliers, for instance, are incorporating machine-learning technology into resource-constrained motion sensors to boost accuracy and power efficiency. The LSM6DSOX iNEMO motion sensors from STMicroelectronics are a case in point. A machine-learning core allows these inertial sensors to classify motion data based on known patterns and, thus, significantly boost the accuracy of gesture and activity tracking.

Moreover, by offloading the main MCU or MPU from tracking complex movements, it significantly improves battery life. The LSM6DSOX motion sensors — comprising a 3D MEMS accelerometer and a 3D MEMS gyroscope — feature a typical low current consumption of 0.55 mA.

STMicro’s IMU incorporates an I3 C digital interface and more internal memory to ensure better handling of interrupts such as tilt detection, free-fall, wakeup, and 6D/4D orientation. (Image: STMicroelectronics)

The machine-learning core, which works in conjunction with the sensor’s integrated finite-state machine logic, can be trained for decision-tree–based classification using the Weka open-source software. Weka is a PC-based software that provides a collection of machine-learning tools for data-mining tasks. That allows developers to generate settings and limits from sample data such as acceleration, speed, and magnetic angle and, based on that, characterize the types of movements that will be detected.

STMicro’s IMU features support free-fall, 6D/4D orientation, wakeup, and click and double-click interrupts that are staples in AR/VR environments. The IMU also simplifies optical image stabilization (OIS) support with auxiliary outputs and configuration options. This significantly boosts the imaging experience and gyroscope performance for the creation of AR/VR worlds.

OIS support brings us to another IMU launched for nascent AR/VR designs: the CORONA motion sensor from InvenSense, now a TDK company.

Already in smartphones

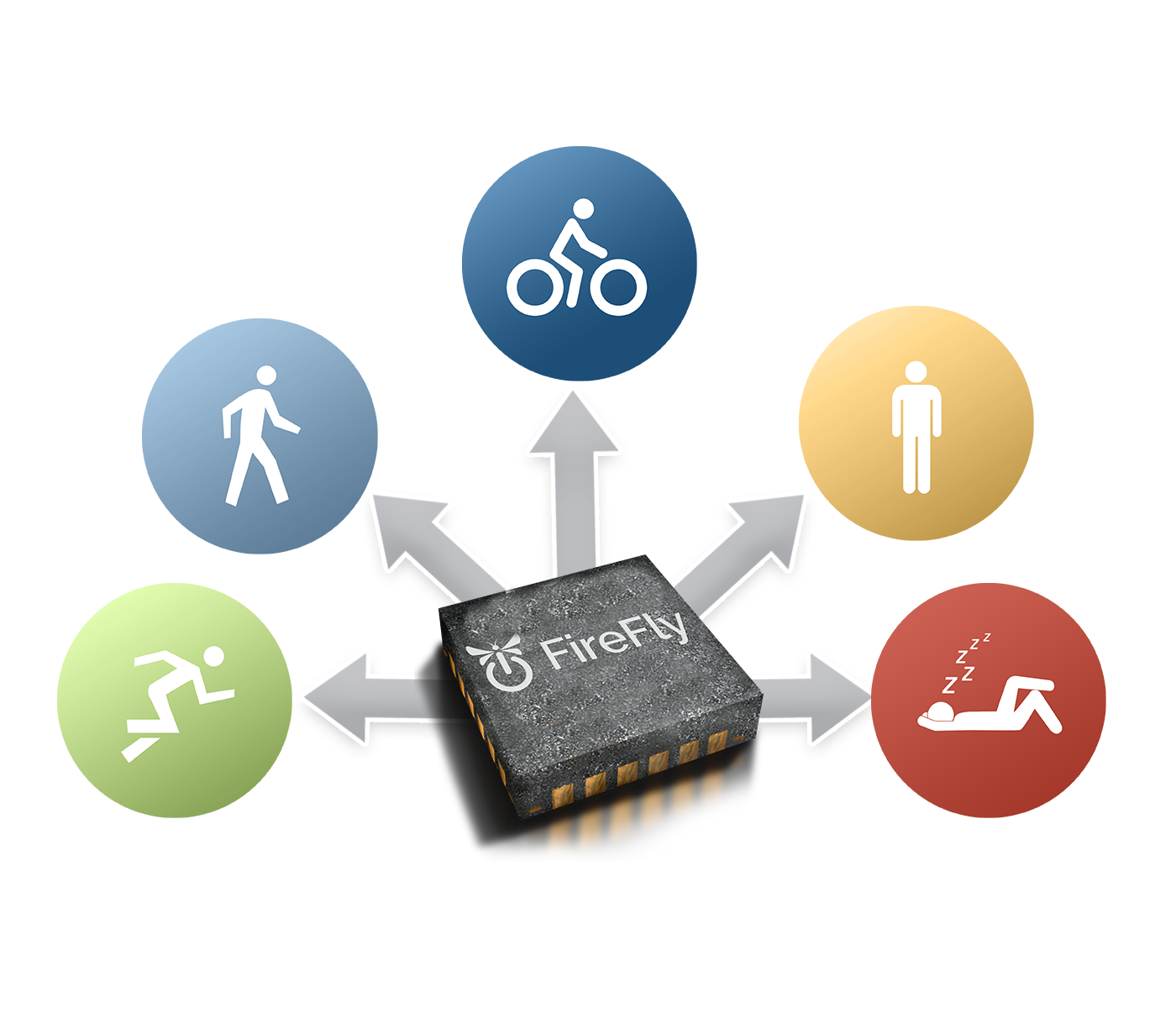

TDK’s six-axis IMU can support two OIS-enabled camera modules simultaneously, which facilitates the concurrent image stabilization in both dual-rear and rear-front smartphone cameras supporting AR/VR features. The IMU’s robust video stabilization at higher frame rates is complemented with TDK’s video stabilization software that synchronizes samples with the sensor hub and eliminates critical timing errors.

The six-axis IMUs ensure highly sensitive, precise, and responsive motion sensing mandated in AR and VR applications. (Image: TDK)

TDK claims that the precise orientation of its CORONA motion sensor — benefitting from reduced sensor noise figures and improved temperature stability — enables a 2× improvement of heading accuracy in AR/VR devices like smartphones. Furthermore, this operational robustness prevents vibrations from distorting the actual device motion measurements.

The chronicle of IMU features, specifically relevant to AR/VR designs, shows that headset and wearable device manufacturers can now count on these motion sensors to eliminate image drifts and deliver a true real-life audio/visual experience. In addition, IMU suppliers like Bosch Sensortec, STMicroelectronics, and TDK are starting to see the AR/VR markets big enough to further hone inertial sensor capabilities for precise orientation and motion granularity.

AR/VR designs appear to have progressed beyond fancy demos, and IMUs warming up to key features and capabilities demanded by augmented and virtual environments is a testament of this shift. More design breakthroughs are expected in the IMU realm with the introduction of new AR/VR gizmos.

Advertisement