By Majeed Ahmad, contributing writer

High-brightness LEDs, or HB-LEDs, are semiconductor-based devices that feature higher luminosity than traditional LEDs, and they can withstand higher current levels and power dissipation. These LEDs provide a better and cheaper lighting experience at relatively lower voltages and are quickly filling the void created by the rapidly disappearing high-wattage incandescent bulbs.

The HB-LEDs feature higher color rendering index (CRI) to make colors look true and natural, and they are fully dimmable without buzzing or humming. That, in turn, mandates higher lighting output — also known as luminous efficacy — to ensure robust color quality. Then there is optical control that ensures there is no crosstalk between pixels in these specialized LED designs.

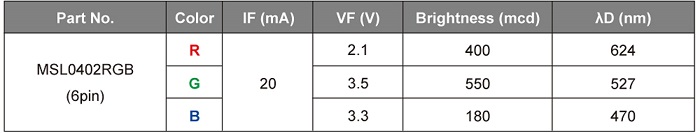

Fig. 1: The operational details of an HB-LED device also showing brightness and output voltage levels. (Image: Rohm Semiconductor)

So far, HB-LEDs have mostly been used in outdoor lighting environments like digital signage and traffic signal lights. However, as they steadily improve brightness consistency and reduce brightness variations, HB-LEDs are proliferating in applications ranging from industrial to consumer to automotive.

A new breed of high-power LEDs facilitates superior color quality and optical control for indoor, outdoor, and portable displays. These HB-LEDs are now used in mobile appliances, automotive daytime lights and tail lights, streetlights, and backlighting in navigation and entertainment displays. Last, but not least, HB-LEDs are becoming a key ingredient in smart home designs by providing high-lumen directional lighting solutions.

The drive for energy efficiency and green electronics is further pushing the HB-LED designs into the smart lighting realm. According to a recent study from Global Market Insights , HB-LEDs are forecast to increase revenue from $4.63 billion in 2015 to $22.46 billion in 2023.

How HB-LEDs work

The HB-LEDs are highly efficient light sources with more light intensity to illuminate indoor, outdoor, architectural, and mobile applications. These high-lumen LEDs emit more than twice as much light as typical LED lighting systems.

The new HB-LEDs also provide highly directional LED lights in a broad array of wattage equivalencies. Take, for example, Cree’s XLamp XP-G2 devices that deliver 25% higher lighting output via a maximum current of 2,000 mA.

These LEDs offer 20% more lumens per watt and 2.5× the lumens per dollar over the original XP-G2 devices. As a result, it lowers the overall system cost by up to 57%. More lumen density also opens new performance venues for space-constrained lighting designs.

A significant rise in operating life is another plus for HB-LEDs that now offer the lifetime of more than 50,000 hours. Not surprisingly, therefore, the long-term reliability and safe operating voltages are making HB-LEDs more popular over traditional lighting solutions.

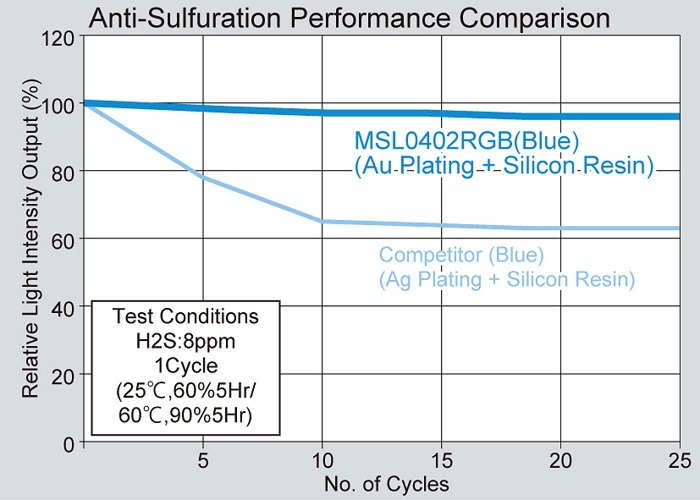

But how do HB-LEDs achieve a longer lifespan? Take the case of Rohm Semiconductor’s MSL0402RGBU device, which uses a gold-plated substrate to prevent sulfuration caused by sulfur components in the air originating from tobacco smoke and exhaust gases. On the other hand, conventional LEDs employ the silver-plated frames and silicon resins that lead to a brightness drop of 30% in a year as a result of sulfuration.

Fig. 2: The anti-sulfuration mechanism in HB-LEDs minimizes brightness degradation and maximizes reliability. (Image: Rohm Semiconductor)

Still, designing low-cost, high-performance, and energy-efficient HB-LEDs presents several challenges. The following section takes a sneak peek into how chipmakers are addressing these crucial design issues.

What matters in HB-LEDs

As mentioned above, brightness degradation is a critical issue in HB-LED designs. Here, Rohm claims that its HB-LEDs reduce the brightness variations by 75%, and this variation reduction, in turn, facilitates a consistent level of brightness. The Japanese supplier is not using binning, the commonly used method for reducing brightness variations, because it mandates additional sorting and use of different resistors.

Instead, Rohm’s SML-D15 series devices employ highly integrated manufacturing techniques to overcome the limits of conventional LED production. These single-rank HB-LEDs, measuring 1.6 × 0.8 mm, claim to improve the brightness by 3× over conventional products.

Miniaturization is another major trend defining the HB-LED designs as lighting applications move to smaller and more sophisticated form factors. For instance, there are ultra-compact reflector-type LEDs optimized for consumer devices like matrix light sources for gaming and wearables.

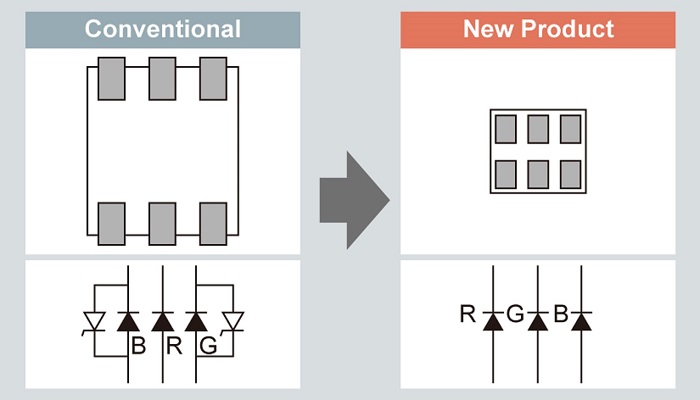

Fig. 3: The new HB-LEDs can pack more energy density in smaller form factors. (Image: Rohm Semiconductor)

Rohm’s MSL0402RGBU reflector-type three-color LED, measuring 1.8 × 1.6 mm, is a case in point. The high-density LED supports high-resolution LED matrices using robust color-mixing characteristics. Moreover, the MSL0402RGBU LED reduces the mounting area by up to 70%.

The lighting designers should also beware of HB-LEDs in high-temperature environments. These high-power LEDs are expected to deliver at least twice the lifetime of conventional LEDs. So to counter the risk of breakdown, HB-LEDs should boost output current and lower thermal resistance to address the ambient temperature effects.

Another vital issue that Rohm’s MSL0402RGBU devices claim to have addressed is protection against ESD effects, which can cause the current to flow from neighboring LEDs and result in light emissions from matrix circuits. While LEDs have traditionally utilized Zener diodes for ESD protection, Rohm’s LED solution integrates a high ESD resistance element and, thus, eliminates the need for a separate Zener protection diode.

The future is bright

HB-LEDs have come a long way from coarse dot-matrix designs that measured as large as 3.5 × 2.8 mm, while their performance deteriorated when they moved to higher resolutions. The decades of LED development efforts in miniaturization have also led to a significantly smaller mounting space compared to conventional LEDs.

Take the example of the VLD.1232 series of blue and true-green ultra-bright LEDs from Vishay Semiconductors. The LEDs offer high brightness with luminous intensity of 16,000 mcd typical, and they come in compact, untinted surface-mount packages with dome lenses. Furthermore, they use sapphire chip technology to narrow the emission angle to ±9° without the need for an external lens.

Fig. 4: The high brightness and compact package make Vishay’s ultra-bright LEDs suitable for a wide range of applications from traffic signals and signs to backlighting audio and video equipment. (Image: Vishay Intertechnology)

The miniaturization trends in HB-LED designs go hand in hand with the drive to overcome the luminosity degradation challenges and to raise the CRI values for better color quality. This shows how quickly HB-LEDs are evolving to improve the visual experience as well as luminous efficacy.

Time is clearly on the side of these high-power LEDs amid environmental concerns and a green electronics design movement. One government after another is putting in place energy regulations that call for energy-efficient LED lighting solutions.

Here, at this lighting technology crossroads, HB-LEDs look more colorful and brighter than ever, promising to transform the lighting experience in industry initiatives spanning from smart buildings to smart cities to smart cars.

Related article:

Avoid damaging inrush current when testing high-brightness LEDs

Tektronix shares tips on how to prevent excessive inrush current when testing high-brightness LEDs and why this is important.

Advertisement

Learn more about Electronic Products Magazine