By Eli Goldin, mechanical engineer I, Inventus Power

As electronic device manufacturers continue to ditch the power cord, allowing unrestricted mobile power, lithium-ion (Li-ion) battery packs are in demand at an all-time high. As technology progresses, devices are becoming more and more power-hungry, and cell manufacturers are developing and launching higher-capacity and higher-power cells. Higher-capacity packs have an increased likelihood and severity of failure, leading to an increased need to ensure the safety of these battery packs.

In 2000, Li-ion battery sales were quickly starting to replace older technologies like nickel-cadmium and nickel-metal-hydride batteries as the go-to rechargeable battery technology, with annual sales contributing to 2 GWh of storage.1,2 Nineteen years later, Li-ion batteries account for more than 120 GWh of added storage each year.2

Li-ion batteries are in higher demand now more than ever as they offer high energy density and power delivery. Today’s lithium-ion cells can reach 700 Wh/L and 330 Wh/kg. By comparison, lead-acid batteries, the widely adopted batteries in most vehicles, can achieve only about 110 Wh/L.3

Li-ion batteries have improved the lives of medical patients, soldiers, and consumers around the world. A patient previously restricted by a power cord can now enjoy life-changing mobility. A typical consumer now has more mobile electronics than ever before, all relying on Li-ion batteries to perform safely and effectively.

When designed and implemented correctly, lithium-ion battery packs are safe and reliable.4 However, these battery packs can become dangerous if designed or manufactured improperly. Furthermore, mechanical abuse resulting in a dent or, worse still, a puncture of a cell in a battery pack can produce volatile results.

Lithium-ion cells have an organic liquid electrolyte containing ions that allow for the transfer of current through the cell. If the cell is subjected to mechanical or electrical abuse in a poorly designed battery pack, and the temperature of the cell increases past a certain point, the cell can experience a phenomenon called thermal runaway.

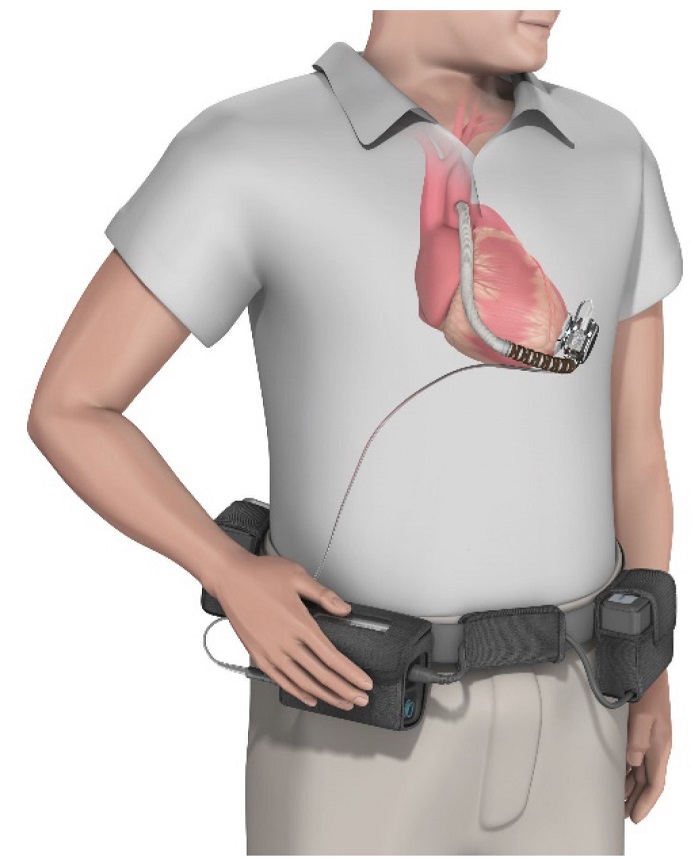

Li-ion batteries in the Medtronic HeartWare HVAD allow patients to live a more mobile lifestyle. (Image: Medtronic)

Thermal runaway is an energetic self-accelerated deterioration of a Li-ion cell, typically caused by an absorption of heat in the cell, triggering a chain of exothermic reactions within the cell. As the cell absorbs heat, it further breaks down and emits thermal energy that is re-absorbed into the deteriorating cell.3

As the cell heats, the liquid electrolyte starts to change phase and break down into organic gas fuels. Flammable gasses fill the cell and pressure builds. This pressure can lead to a violent release of pressurized flammable gasses, molten metal, and, if ignited, hot flames. Flames from a thermal runaway of a single Li-ion cell can reach upwards of 1,200°C.5

Now imagine 10, 100, or 1,000 cells in a pack, and the importance of creating a safe battery pack becomes clear. Thermal runaway battery disasters have happened on a very public stage, such as when a pack on a Boeing 787 Dreamliner caught fire parked at the gate at Boston’s Logan International Airport or when Samsung Galaxy Note 7 phones were banned on airplanes in the U.S. due to design flaws that caused some thermal runaway events.6,7

So what can be done to prevent Li-ion battery disasters? The answer is that every company involved in the production of a Li-ion battery, whether it be the cell, battery pack, or device manufacturer, has a unique responsibility in developing safe battery technology. Close communication between each company in the value chain is imperative to create safe and harmonious implementation of the battery packs.

Cell manufacturers have an obligation to manufacture in a clean environment to ensure the utmost quality in each cell they create. Even small defects in a cell can lead to a short-circuit, allowing for an uncontrolled temperature increase.5 Battery pack manufacturers, in turn, need to design a pack that can prevent thermal runaway even when operating in extreme conditions or when a failure occurs within a cell.

They do this by adding several levels of protection onto a circuit that controls the pack, preventing the major causes of thermal runaway such as overcharge, overdischarge, and cell-voltage imbalance. Such a circuit can also recognize dangerous increases in temperatures and shut down operation of the pack. Finally, the device manufacturers need to design a system that draws power from the battery pack as agreed upon by all manufacturing parties involved. Inadequate design or quality by any one of these contributors can lead to a Li-ion battery disaster.

Leading battery pack manufacturers often incorporate up to three levels of protection to prevent thermal runaway of a cell. Despite this safety factor in the design, it is reasonable to assume that in some cases, extreme events can cause thermal runaway of a cell. For example, thermal runaway of a punctured cell is almost impossible to prevent. When this does occur, it is imperative to prevent propagation of thermal runaway to the neighboring cells in a pack. Doing so could make the difference between a significant failure and a catastrophic battery disaster.

Simply put, a battery pack that prevents thermal runaway propagation must prevent heat transfer from the trigger cell into the surrounding cells. A single-cell thermal runaway event can generate roughly 3 MJ of thermal energy.3 This energy will exit the cell in the form of light, flame, molten ejecta, and heated gas. All of this energy needs to be redirected or absorbed in some way.

The first step in designing a safe battery pack that can prevent thermal runaway propagation is to perform heat transfer and flow analysis in the design phase to predict where energy and gas from a thermal event would spread. This analysis will allow an engineer to identify the critical areas of the battery at risk for thermal energy absorption. Given this analysis, a design can be created to optimize the safety of the pack.

In cylindrical cells, pressure and gas often release out of the positive end of the cell. Existence of a direct thermal path between cells without any impediments or blockades will nearly always result in propagation.3 Therefore, it is best to avoid orienting cells with the positive end directly facing the negative end. However, this is not the only consideration when laying out cells. Depending on the cell design, side ruptures can occur during thermal runaway events.

Core pack cell carriers provide significant support in preventing thermal runaway propagation. Cell carriers can add spacing between cells in a pack, direct pressure buildup out of the positive end of the cell, and prevent runaway cells from moving and colliding into other cells.

In addition, the pack must block molten ejecta from contacting a neighboring cell and suppress combustion of the vented gasses from the trigger cell, all while cooling down the trigger cell and releasing heat away from neighboring cells. Material selection is critical to achieve this additional safety. Intumescent materials to suppress a fire in the event of thermal runaway have been proposed in certain designs, but they cannot stand alone as the only protection against thermal propagation. It has been shown that even halons like those in a household fire extinguisher put out the fire in a lithium-ion cell for only a short period of time, after which the cell can reignite.5

In addition to intumescent materials, including flame-proof materials between cells and the outside housing can help prevent thermal propagation and harm to the end user caused by flames exiting the pack. In a thermal runaway event, molten ejecta and flames can exit the cell with ferocious speed. Including flame-arresting screens and designing a path for the ejecta and flames to follow will help reduce the risk of flames and sparks that exit the battery.8

In larger packs, it is critical to incorporate passive or even active thermal management techniques. Phase-change materials can absorb and spread heat uniformly throughout a pack, reducing concentrations of heat on neighboring cells. Active heat exchangers have also been deployed to reduce heat concentrations in areas of a battery pack. These techniques have also been shown to increase battery life, as they slow degradation of cells during high-rate discharge cycling.

No matter what stage of the value chain a company handles for devices powered by Li-ion battery packs, engineers have a moral obligation to design the safest-possible battery pack. Cutting corners is not acceptable and the best practice methods for preventing battery disasters should become industry standard for devices incorporating Li-ion batteries.

The benefits of Li-ion batteries are numerous, and these batteries are essential to the success of many businesses developing devices that contribute to human progress. The unique safety issues inherent to lithium-ion technology can be controlled and made as safe as possible by design engineers who implement innovative solutions that play an important role in guaranteeing battery safety.

References

1 2018, “Is Lithium-ion the Ideal Battery,” Battery University, from https://batteryuniversity.com/learn/archive/is_lithium_ion_the_ideal_battery.

2 Nakhleh, R., Principle Application Engineer at Inventus Power, 2018., “Lithium Ion Battery and Market Trends,” Lecture.

3 Sturnfield, Lucas, 2017, “How to Prevent Battery Disasters,” Medical Device and Diagnostic Industry Online, from https://www.mddionline.com/how-prevent-battery-disasters.

4 2018, “BU 304a – Safety Concerns with Lithium-ion,” Battery University, from https://batteryuniversity.com/learn/article/safety_concerns_with_li_ion.

5 Long, R.T. PE., Mikolajczak, C. PE., Kahn, M. PhD., White, M. PhD., 2011, “Lithium –Ion Batteries Hazard and Use Assessment,” Exponent Failure Analysis Associates, Inc. and The Fire Protection Research Foundation, Quincy, Massachusetts, USA.

6 2016, “DOT Bans All Samsung Galaxy Note7 Phones from Airplanes,” U.S. Department of Transportation, from https://www.transportation.gov/briefing-room/dot-bans-all-samsung-galaxy-note7-phones-airplanes.

7 2013, “NTSB Case Number: DCA13IA037 – Boeing 787-8, JA829J, Japan Airlines,” National Transportation Safety Board, Boston, Massachusetts, USA.

8 Jeevarajan, J., PhD., NASA-JSC, 2010, “Safety Limitations Associated with Commercial 18650 Lithium-ion Cells,” Lithium Mobile Power and Battery Safety 2010.

Advertisement

Learn more about Electronic Products Magazine