By Alex Pluemer, contributing writer

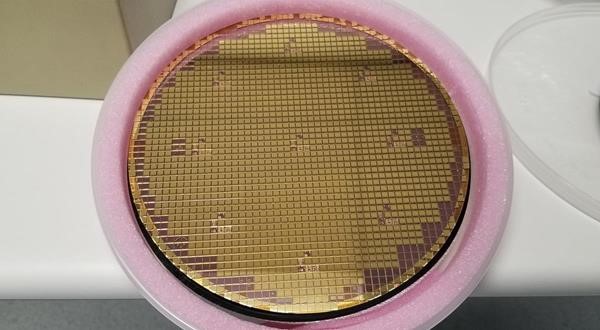

Menlo Micro has announced that its new Digital-Micro-Switch (DMS) technology platform, demoed in June 2018, has moved from research and development into production at pure-play MEMS foundry Silicon Microsystems. The company is now producing samples of its new microelectromechanical (MEMS) switches on an 8-inch wafer manufacturing line and expects to scale up production by the end of the year.

The DMS technology incorporates through-glass-via (TGV) technology from Corning Inc. The TGV packaging technology is a major factor in the increased performance offered by Menlo’s DMS products. Package parasitics are reduced by more than 75% by replacing wire bonds with metallized vias — a change that also provides support for the increasingly higher frequencies required by communications systems, test instrumentation, and a variety of defense and aerospace applications. Using glass instead of conventional substrate materials (such as silicon) reduces RF losses and enables higher linearity, further lowering power consumption and increasing overall efficiency.

The company’s switches are built in a structure that is smaller than a single human hair but can handle kilowatts of power while operating up to 1,000× faster and for 1,000× longer than conventional mechanical relays.

Menlo has taken advantage of advancements in processing, packaging, and advanced alloys to reduce the size of its components by as much as 60% compared to their predecessors. The company’s own material science innovations have simplified the manufacturing process to the extent that Menlo implements 30% to 40% fewer manufacturing steps than conventional CMOS processes, which helps to reduce manufacturing costs. Menlo transferred its DMS process, developed at GE Global Research, to Silex Microsystems.

“In less than two years, we’ve been able to successfully transition our robust and reliable MEMS switch process from a research environment to a true production fab,” said Chris Keimel, CTO for Menlo Micro, in a statement. “In this period of time, we have also achieved several key technical milestones — most notably, the integration of Corning’s TGV substrates with Menlo’s MEMS switch process to deliver a miniaturized, chip-scale-package solution for our products. Scaling the process to an 8-inch production line is a significant step that brings size, cost, performance, and manufacturability improvements to Menlo’s DMS products — and demonstrates that the technology can, indeed, be scaled to commercial levels.”

Menlo has already shipped over 100,000 units from its existing manufacturing line. The company, in collaboration with Corning and Silex, plans to scale up production to bring its high-performance RF and power products into a wider variety of end markets. The new MEMS switches will bring step-function performance improvement to applications such as industrial automation, test and measurement instrumentation, military communications, medical equipment, and 5G networks, said the company.

Advertisement