OmniVision Technologies, Inc. has developed a line of turnkey medical imaging subsystems for single-use endoscopes and catheters that consist of the camera modules, image signal processor (ISP) boards, and cables. Announced at CompaMed, the end-to-end imaging solution combines the company’s medical CameraCubeChip wafer-level camera modules, OVMed ISP boards, and new OVMed Cable line.

The addition of the OVMed line of medical endoscope, catheter, and dental cables enables OmniVision to offer a complete imaging platform, joining its family of CameraCubeChip camera modules and OVMed ISP boards. This allows medical device OEMs to focus on differentiating their endoscope and catheter designs, while accelerating time to market.

“Supplying the end-to-end imaging subsystem is very appealing to a certain class of customers because they want to focus on making the medical device and not get bogged down with the image subsystem,” said Tehzeeb Gunja, director of medical marketing at OmniVision. “Having said that there are vertically integrated customers who say, ‘I can make the imaging subsystem – all the bits and pieces – but I just need the image sensor,’ so it is an à la carte model depending on what the customer needs.”

A key driver behind the growing demand for single-use, or disposable endoscopes, is cross contamination. There is also a growing requirement for higher image resolution in small-diameter applications.

The biggest problem is cross contamination with the use of reusable endoscopes, said Gunja. People have died from improperly cleaned reusable scopes, so it is a big problem in terms of liability and cleaning, he added.

“This market is being pushed by the addition of video and the shift toward small-diameter applications needing higher image resolutions. Additionally, medical trends are favoring single-use devices, including cross-contamination issues and strong regulations stemming from endoscope disinfection matters,” said Jérôme Mouly, team lead analyst for sensing at Yole Développement, in a statement.

“The ramp up is starting this year and will continue in the coming years as regulators enforce the use of disposable endoscopes for certain procedures, such as bronchoscopy, laryngoscopy and urology,” he added.

Cost also is an issue. The top-end reusable Olympus scope costs about $25,000 and if you buy 10 of them that is a quarter of a million dollars plus the cost of the backend system, said Gupta.

“So you’re easily looking at a multi-million dollar upfront investment, which is recouped after 10 or 15 years, so a small hospital or small clinic would find it difficult to make that kind of investment,” he said.

“With a single-use device it’s literally pay as you go,” Gupta added. “You buy five of them; you use them, so it now becomes an operational expense. When you get paid, you pay your supplier, so you’re not tying up a lot of money.”

Part of the challenge of designing a disposable endoscope is the lens cost. “The cost of the lens was an inhibitor of making a single-use device. A traditional glass lens, which is used in an endoscope can cost anywhere between $150 to $200 dollars, so right away the question of single-use goes out the window,” said Gupta.

OmniVision developed a technology called wafer-level optics that allows for the use of a $8-$10 lens with good image quality that is supplied as part of one complete module, he said.

Camera modules

The camera module is a key component of the imaging subsystem for disposable medical devices. OmniVision’s CameraCubeChip integrates the image sensor, ISP, and lens in a miniature wafer-level camera module. For medical applications, the company has been working to increase the resolution and quality of the images captured during endoscopic and catheter procedures.

OmniVision recently teamed up with Almalence Inc., a provider of computational imaging, to develop a joint solution for endoscopic medical imaging. The new solution combines OmniVision’s smallest wafer-level camera module, as well as the industry’s smallest sensor, with Almalence’s Super Resolution technology.

Together, these technologies increase the sensor’s resolution and quality of the images captured during endoscopic and catheter procedures across all disciplines, such as neurology, ophthalmology, otolaryngology, cardiology, orthopedology, gynecology, and urology.

OmniVision’s OVM6948 CameraCubeChip (Image: OmniVision)

The solution is built around OmniVision’s OVM6948 CameraCubeChip wafer-level camera module that measures 0.65 × 0.65 mm, with a z-height of only 1.158 mm. Almalence pre-tuned its Super Resolution algorithm, which is currently the de-facto standard for smartphone cameras, according to the company, which effectively increases the OVM6948’s backside-illuminated resolution by 1.5x to 300 × 300 pixels array (from 200 × 200) and boosts its signal-to-noise ratio (SNR) by up to 8 dB for a total of about 42 dB.

These increases would otherwise double the image sensor and camera size, due to the required increase in pixel count, said Gunja. “Until now, medical device designers were forced to make a trade-off between size and resolution.”

The problem is that endoscopes tend to be small – they’re going inside the heart, spine, brain and the eye, so there’s a lot of pressure to make things smaller, he said. “If you want a higher resolution, you need to use a larger pixel size, so you’ll end up with a large image sensor that is too large for that class of endoscope.”

What is needed is a solution that uses small pixels to provide a high resolution with small dimensions, but it can’t be solved from an image sensor point of view, he added. “These are competing requirements. But we can do it from a post-processing point of view which is where Super Resolution comes into play. It overcomes this resolution and image quality trade-off by improving the resolution and the image quality without increasing the size of the camera.”

The result is an image sensor with a 1.75-micron pixel size that behaves as if it has a 300 × 300 resolution and 2.6 micron pixels. “Not only have you solved the resolution problem but you’ve also solved the small pixel problem at the same time by doing something clever as part of the post processing of the algorithm,” said Gupta.

The OVM6948 camera module integrates OmniVision’s OV6948 image sensor, which holds the Guinness World Record for “The Smallest Image Sensor Commercially Available” with its size of 0.575 × 0.575 mm. Because the CameraCubeChip optics are fabricated at the wafer level, they can be bonded to this image sensor to form a camera module that measures only 1.158 mm high. This enables integration into an endoscope or catheter with a diameter of less than 2.0 mm.

Almalence’s Super Resolution algorithm increases the sensor’s effective resolution by not only making the image look sharper and smoother, but also reconstructing more details, as if it were captured with a higher resolution sensor, according to Gupta. Additionally, the algorithm’s computational load is optimized to run on any major SoC or DSP, leaving plenty of headroom for other processing tasks.

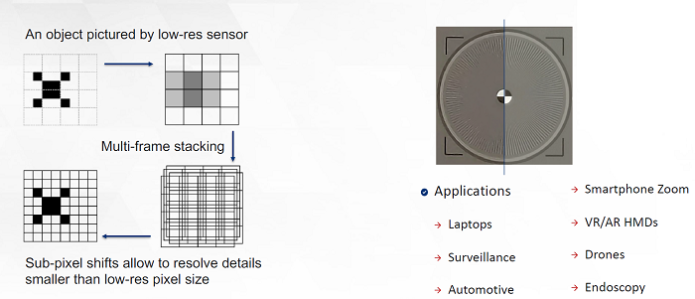

Almalence’s Super Resolution technology (Image: OmniVision)

How does it work? Almalence uses multi-frame imaging, or a series of images, to achieve a higher resolution, SNR, and dynamic range.

Fundamentally, what Almalence does is to take multiple images, said Gupta. “Across each image, the information in a pixel changes slightly over time and that is what they are exploiting – the time difference across multiple images. Then they stack the multiple frames and it’s that pixel shift that essentially allows them to create a high-resolution image. There are a number of different applications for the technology, not just medical.”

“We really feel that we are advancing health care and as a result of our efforts we feel that we are transforming lives,” said Gupta. “There is a social element to what we do, which is to improve the patient outcome for the patient and for the doctor.”

OmniVision’s OVM6948 CameraCubeChip module is available now for sampling and mass production. The license of Almalence’s Super Resolution algorithm also includes tuning services for any OmniVision medical image sensor in combination with any lens available on the market—at every stage of development, from initial design to product launch.

Almalence provides a software development kit with its license, featuring numerous parameter APIs for additional tuning by medical device designers.

ISP boards

The turnkey subsystem also offers a selection of OVMed ISP boards available in either “mini” or “advanced” modules. The mini modules offer cost-effective performance and reduced size and fit inside the handle of the endoscope, while the higher performance and larger-sized advanced feature boards can be incorporated into camera control unit (CCU) systems for higher resolution images. They also can fit into the handle of larger-sized endoscopes.

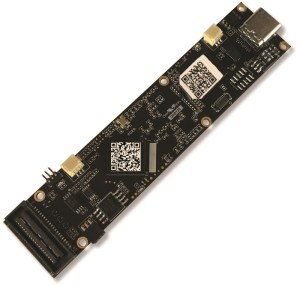

OmniVision OH0130 ISP board (Image: OmniVision)

The mini modules offers a variety of outputs including USB, Wi-Fi, and 3D as well as a parallel output. They can handle either analog or digital inputs. The advanced versions can provide USB and HDMI along with advanced features such as snapshots, graphics, and storage.

A few examples include the mini class 3D OH0142 for stereoscopic 3D imaging with dual-input capability, which can process inputs from two image sensors/cameras in parallel to augment the surgeon’s view, and a mini wireless (Wi-Fi) ISP module, the OH0137, that enables data to be transmitted to any kind of device such as tablets, and provides user-configurable buttons and wireless control.

One of the newest members of the mini class ISP modules is the OH0130 with MIPI and analog input interfaces and a USB 3.0 Type C HD output. This is a cost-effective option for CCU systems that can process higher and full-HD resolution images up to 1080p. It’s also small enough to fit into the handle of a larger endoscope.

Gupta said it can do everything the other ISPs do, as well as drive an LED, and deliver all of the backend ISP features, like brightness, contrast, saturation, sharpness, gamma, hue adjustment, BLC, lens shading compensation, defective pixel removal, and de-noise.

Medical cables

Also new from OmniVision are the OVMed Cables for the turnkey imaging subsystems. The company enters the cable market with two classes of cable for a single-use endoscope: a short cable (1.5 to 2.5 meters) and long cable (4 to 5 meters).

OmniVision outsources the manufacturing to a cable manufacturer, which enables it to provide semi-custom cable design solutions to meet different customer requirements. OmniVision completes the backend certification, qualification, and testing that includes tests for banned substances, operation tests, stress tests, sterilization, bio-compatibility, and workmanship.

OmniVision’s OVMed cables (Image: OmniVision)

“Previously, endoscope and catheter designers had to source cables from multiple vendors, as no one offered cables for all of our CameraCubeChip modules, which created both supply chain and imaging subsystem tuning challenges,” said Gunja. “With the introduction of our OVMed Cables, we now provide OEMs with a single source of supply and support for the entire medical imaging subsystem, covering our whole portfolio of medical camera modules and ISPs, and tuned for optimal performance by our imaging experts.”

OVMed Cables provide high image quality with minimal artifacts for the transmission of captured images from the endoscope’s distal tip, down the endoscope shaft to the proximal end. These semi-customizable cables are optimized for small module size, thin diameter, flexibility, mechanical robustness, and cost.

Customizable parameters include short cables of 2.5 meters or less, long cables up to 5 meters, analog or digital MIPI output from 200 x 200 at 30 frames per second (fps) up to 720p resolution at 60 fps, as well as a wide range of connectors—with or without LED illumination. The company plans to add a digital MIPI output with a resolution of up to 1080p at 60 fps.

The OVMed cables are electrically shielded for electromagnetic compatibility (EMC) and interference (EMI), which allows the cables to withstand energy discharges during multimodal medical imaging procedures inside the body, while eliminating interference with other devices in the operating room.

The new OVMed Cables are sampling today, with volume production expected in 2021.

Advertisement

Learn more about OmniVision Technologies