By Richard Quinnell, Editor for Special Projects, Technical

A few years ago, 3D printing in manufacturing operations was full of promise but still unproven. Since then, it has descended, according to the Gartner Hype Cycle , into the “trough of disillusionment,” in which reality falls short of expectations. But none of that disillusionment was in evidence at April’s Hannover Fair, one of the world’s largest industrial trade shows. There, 3D printing was on abundant display, showing that 3D printing is gaining momentum in modern industrial operations.

The essential process of 3D printing, aka additive manufacturing, seems simple. Moving in a horizontal (X-Y) plane, the printing mechanism deposits on a build platform a thin layer of material corresponding to a cross-sectional slice of the target object. Then either the printhead or the substrate moves slightly in a vertical (Z) direction and the process repeats to lay material for the next slice against the previously deposited material. When the process is complete, and the support material removed, the resulting stack of slices is the full 3D object that was desired.

Three main types of printing mechanism were in evidence at the Fair — extrusion, sintering, and photolithographic — with multiple vendors for each of the three types. HP also had its hybrid jet fusion 3D printer on display. Several suppliers of printing materials also had a presence.

Gaining momentum in industrial applications, the 3D printers on display at the Hannover Fair are far removed from their hobbyist roots. Image: HP.

Each type of printing mechanism offers a choice of materials from which to fabricate objects as well as unique opportunities and challenges. Extrusion printing, for instance, typically works with plastic filaments that printheads must melt to extrude and deposit when building up an object. An alternative uses ink-jet heads to deposit material in droplets. Either way, the approach creates a problem if an object’s structure has an aggressive overhang or features that start somewhere in the Z-axis with nothing below them. Because the printer cannot deposit material on air, or even cantilever too far from its base, the extrusion process requires that the printer create support posts where needed. This adds complexity to the object’s description file, wastes material, and requires post-print cleaning of the object to remove the support structure.

Industrial 3D extrusion printers are addressing this challenge, though, in several ways. One is to utilize a multi-head printer with one of the heads printing the object material and another head printing a different support material. That support material may be formulated for easy breakaway from the object’s base material or might be something like the water-soluble polyvinyl alcohol (PVA), which can be removed using a solvent.

Sintered 3D printing bypasses the need for creating support structures because the work in progress always has the support of base materials. These printers work by depositing a layer of powdered material on the build platform and then selectively fusing the powder into a solid to build up the slices. Typically, that fusion process utilizes a laser to generate pinpoint heating, scanning the beam across the build area, but other approaches are also available. HP, for instance, uses what it calls jet fusion, leveraging its ink-jet printer technology for the application of chemical fusion agents onto the powder layer. Envisiontec’s Viridis3D printer works with sand, applying a binding agent to fuse the grains together.

One advantage to the sintered printing is the range of materials available for building objects. Unlike extrusion, which requires the build material to have a low-enough melting point that the printhead can handle, laser sintering can work with materials having very high melting points. This allows, for instance, the use of metals such as nickel, steel, or titanium as well as various types of ceramics. One drawback of sintering, though, is added printer complexity. Not only must the printer be able to lay down a thin, even layer of powder for each new layer, it must be able to efficiently recover and re-use the un-sintered powder once the build is complete.

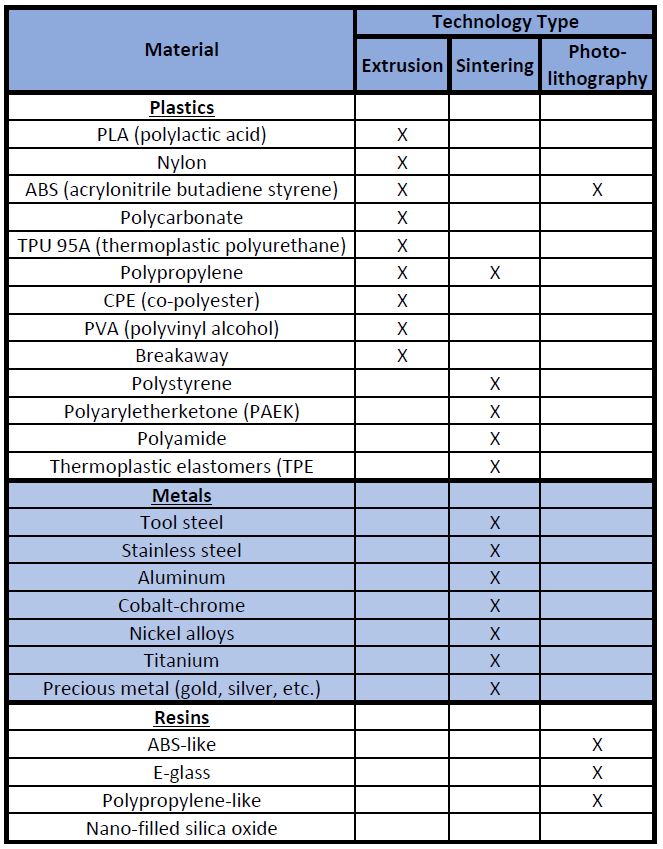

The third major 3D-printing process, stereolithography, also selectively hardens material covering the build platform, but instead of a powder, it uses a liquid. Dual, focused light sources trigger the curing of a photo-hardened resin when both beams are focused on the same spot or voxel (volume pixel) near the fluid’s surface. The printer then raises the build platform slightly to set up for the next slice. The build object is thus drawn out of the liquid, eliminating the need to remove unused material from the build area to set up for the next print run. The disadvantage to the approach is the limited range of photo-curable build materials available. A summary of representative build materials for all three processes is given in the table below.

Representative build materials for use in 3D-printing technologies.

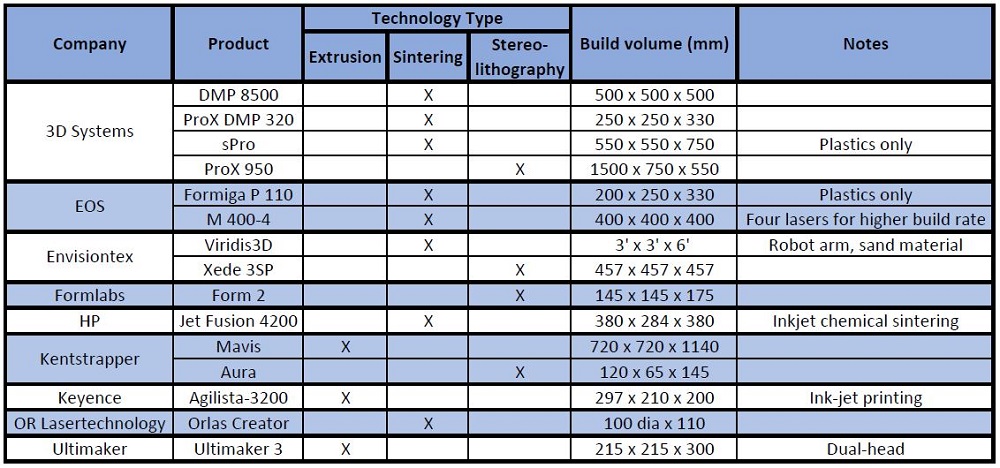

Once considered a novelty, even a toy, 3D printing is now recognized as a viable approach to the creation of prototypes and unique or custom items. For larger-scale manufacturing, however, 3D printing faces several limitations. One is object size — the item to be fabricated must fit within the volume defined by the device’s movement limits. The build volumes for representative printers are listed in the table below.

Representative industrial 3D printers.

Two additional limitations are fabrication speed and precision, both interrelated. Because printers fabricate in layers or even individual voxels, object precision and surface smoothness are limited by the layer thickness or voxel size in use. At the same time, fabrication speed is inversely related to those same dimensions. The finer the detail, the slower the fabrication process.

These limitations can restrict the applicability of 3D printing in industrial applications, in which high-precision and high-volume production are often paramount. But the momentum for industrial 3D printing is growing, with vendors steadily chipping away at these limitations. Layer thickness is already as fine as 20 microns for many industrial printers, with 12-micron X-Y position accuracy for voxels, and improvements are ongoing.

Another method for increasing the precision and surface smoothness is to adopt a hybrid fabrication approach. The ship’s propeller shown below, for instance, was roughly fabricated using laser sintering, then machined down to exact dimensions and surface polish using conventional CNC equipment.

A combination of 3D printing and conventional machining allows rapid creation of precision custom objects such as this ship’s propeller. Image: Rich Quinnell.

To boost 3D printer production speed, several approaches were on display at the Fair. The HP Fusion Jet and Viridis3D printers, for instance, use a linear array of printheads to sinter material on the build surface with a single pass. Similarly, the EOS M400-4 employs four lasers in its sintering process to speed throughput.

Build volume limits are also being addressed. The Viridis3D printer and an IKV demonstration unit used a robotic arm to control printhead position rather than having an X-Y scanning mechanism and separate Z-axis platform movement. So instead of requiring the part’s fabrication to take place within (and be limited by) the printer’s enclosure, the robot additive manufacturing (RAM) approach can build the object out in the work environment on any surface desired. This approach also expands the build volume to whatever the arm can reach. The Viridis3D printer, for instance, can create objects as large as 3 x 3 x 6 feet.

The momentum that 3D printing is gaining in industry is also the result of changes within the manufacturing industry itself. There is an increasing demand for customization of production in form factor, color, and materials as well as interest in reducing inventory by creating parts on demand instead of stockpiling them. Also, production lines are having to become more flexible, able to quickly adapt to changing demands. Efficient 3D printing can address all of these demands. With such market needs driving demand, 3D printing will only continue to gain momentum in industrial applications.

Check out these other articles in the Industry 4.0 Special Report:

Hannover Fair shows off the factory technology of tomorrow — Four key trends emerged from the massive assemblage that is industry’s biggest annual showcase.

Robots are becoming more helpful, easier to use, and friendlier — At the Hannover Fair this year, industrial robots showed both utility and coworker compatibility.

Mixed reality: The software is willing, but the hardware is weak — While augmented and virtual reality applications for industry are blossoming, headset limitations remain an impediment to widespread adoption.

“Digital Twins” enable machine simulation & maintenance, Industry 4.0 — Marry EDA to the Industrial IoT to birth Digital Twins for system-level maintenance, simulation, and optimization.

Related articles from the ASPENCORE network:

Fear Not the Cobot — Discussing the newest and perhaps most exciting realm of industrial robotics: collaborative robots.

Meet the TI Robotics System Learning Kit — An exciting new university robotics kit and teaching tools from TI will help prepare future engineers for system-level design.

Advertisement

Learn more about Electronic Products Magazine