Cooling and other issues derived from scaling continue to obstruct nanoelectronics from reaching their full disruptive potential. Preventing the heat build-up at the nanoscale from damaging embedded electronics remains challenging, but researchers from Rice University determined that a few nanoscale adjustments enable graphene-carbon nanotube junctions to excel at transferring heat away from nanoelectronics and preventing structural damage.

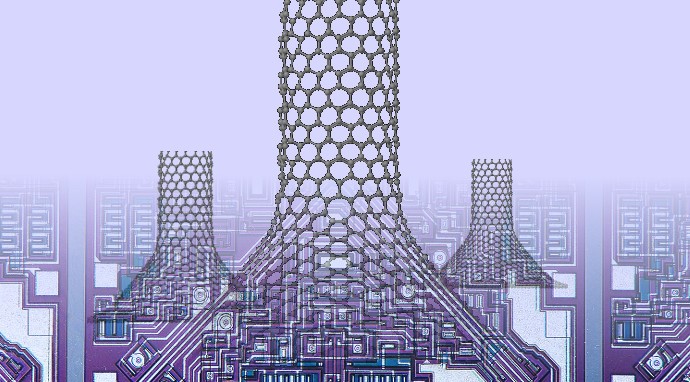

In theory, all it takes is building a cone-like “chimney” between the graphene and nanotube to give heat a way to escape. That’s what Rice University theoretical physicist Boris Yakobson claims in a research paper published in the American Chemical Society’s Journal of Physical Chemistry C.

Graphene nanotubes, like carbon nanotubes, excel at rapidly transferring electricity and phonons — atoms or molecules in condensed matter that collectively behave in an excitation state to create physical properties like electrical conductivity. Both types of nanotubes consist of six-atom rings that form a chicken wire-like mesh, but when a nanotube is grown from the graphene itself, the atoms create a seven-sided heptagonal ring that’s excellent for storing hydrogen for energy applications but scatters phonons and restricts the release of heat.

Yakobson and his team discovered — by way of simulation — that removing atoms from specific points in the two-dimensional graphene base forces a cone to form between the graphene and the nanotube. The resulting geometric properties require the same number of total heptagons and leave a clear path for the dissipation of heat from nanoelectronics.

“Our interest in advancing new applications for low-dimensional carbon — fullerenes, nanotubes, and graphene — is broad,” Yakobson said. The “chimneys” may be used as building blocks to fill three-dimensional spaces with different designs, “creating anisotropic, non-uniform scaffolds with properties that none of the current bulk materials have. In this case, we studied a combination of nanotubes and graphene, connected by cones, motivated by seeing such shapes obtained in our colleagues’ experimental labs.”

The Rice team’s simulation tested phonon conduction using free-standing nanotubes, pillared graphene, and nano-chimneys with a cone radius of 20 or 40 angstroms. Each offered a different degree of conductivity. The pillar graphene was 20% less conductive than plain nanotubes, while the 20-angstrom nano-chimneys were as conductive as the plain nanotubes. The nano-chimney whose diameter measured 40 angstroms offered a 20% improvement over the nanotubes.

“The tunability of such structures is virtually limitless, stemming from the vast combinatorial possibilities of arranging the elementary modules,” said Alex Kutana, a Rice research scientist and co-author of the study. “The actual challenge is to find the most useful structures, given a vast number of possibilities, and then make them in the lab reliably.”

To read Yakobsen’s paper, visit http://bit.ly/2jUzOEQ .

Advertisement

Learn more about Electronic Products Magazine