By Andrew Dereka, product director, Laird Thermal Systems

Offering an alternative to conventional fan trays and compressor-based cooling systems, thermoelectric cooler assemblies are compact units that deliver precise temperature control. These cooling assemblies serve a cooling capacity spectrum from approximately 10 to 400 W and can cool by removing heat from control sources through convection, conduction, or liquid means. They are used in a variety of applications, including sample storage compartments in analytical instrumentation, chambers in medical diagnostics, industrial and medical lasers, and electronic enclosures.

At their core, thermoelectric assemblies use thermoelectric coolers, which are solid-state heat pump devices that pump heat via the Peltier effect. During operation, DC current flows through the thermoelectric cooler to create heat transfer and a temperature differential across the module.

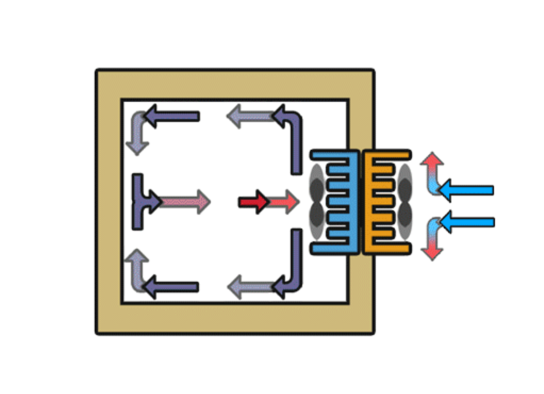

Removing heat from inside of a cabinet is illustrated below. One side of the thermoelectric cooler is cold, while the other side is hot. To move heat away, heat-absorption and heat-dissipation mechanisms (heat exchangers) within the thermoelectric cooler assembly are connected to thermoelectric coolers. The cold-side heat sink absorbs heat from inside the cabinet, while the hot-side heat sink dissipates heat to the ambient environme

Heat from the application is absorbed by the cold-side heat sink (blue) in the thermoelectric cooler assembly and dissipated to the outside environment through the hot-side heat exchanger (orange).

Thermoelectric cooler assemblies offer several advantages over alternative cooling technologies. For example, conventional fan trays do not cool to below ambient temperature and require an air exchanger with the outside environment. Thermoelectric cooler assemblies, however, can cool to well below ambient and protect electronics inside sealed enclosures from outside contaminants.

Other advantages include:

- Compact form factor

- Ability to heat and cool, resulting in precise temperature control

- Solid-state construction, providing long-term reliability with few moving parts

- No field maintenance requirement, which lowers the total cost of ownership

- Lower noise and vibration

- Mountable in multiple orientations

- Environmentally friendly, as no hazardous CFC refrigerants are used

Compact form factor

Small size and lightweight construction make thermoelectric assemblies ideal for applications that have tight geometric space constraints or low weight requirements. Traditional cooling technologies, such as compressor-based systems, are much larger and heavier when compared to thermoelectric technology.

Heating and cooling

By reversing the polarity on the thermoelectric cooler, a thermoelectric cooler assembly can be used in heating mode. This is useful for a wide variety of applications, including outdoors, where temperatures can drop below the lower temperature limit of sensitive electronics or batteries. This also eliminates the need for a resistant heater that would be used in traditional compressor-based systems, lowering costs and complexity.

Bidirectional control

For cabinet cooling, it is common to use a bidirectional controller to keep the cabinet between two temperature set points. For example, a temperature controller can turn on the cooling mode of the assembly once the upper temperature set point has been reached. Similarly, the controller can turn on the heating mode once the lower temperature limit has been reached. A hysteresis setting is used in conjunction with the temperature limit set points to set the desired degrees of the thermoelectric cooler assembly during cooling or heating.

Solid-state construction

With fewer moving parts in the system, thermoelectric cooler assemblies offer reliable solid-state operation with almost no maintenance, resulting in lower cost of ownership. For areas with a high concentration of dust, a filter is recommended, and on occasion, heat sinks should be cleaned with compressed air to remove dust. This ensures a more efficient cooling system with long-life operation.

Fewer moving parts also means there is less noise and vibration. Most high-quality thermoelectric cooler assemblies utilize low-noise components. In addition, solid-state construction allows a thermoelectric cooler assembly to be mounted in most any direction, simplifying design and installation.

Environmentally friendly

Strict government regulations ban the use of traditional refrigerants central to many compressor-based systems. Older compressor-based systems utilize high-global-warming-potential HFC refrigerants including R134a and R404A. Modern compressor-based systems now use a variety of natural refrigerants: R744 (carbon dioxide), R717 (ammonia), R290 (propane), R600a (isobutene), and R1270 (propylene).

However, each natural refrigerant presents design challenges such as increased pressure, high toxicity, flammability, asphyxiation, and relatively poor performance. The flammable nature of some natural refrigerants makes them hazardous to transport.

Because solid-state thermoelectrics use no refrigerants, these compact assemblies are a popular, environmentally friendly alternative for many cooling applications.

Customization

Thermoelectric cooler assemblies are available in a variety of standard heat pumping capacities, sizes, heat transfer mechanisms, and voltage ranges. One can also specify a custom assembly to match unique space constraints or environmental requirements. The thermoelectric coolers embedded in the assembly can also be customized to maximize performance and efficiency for the intended application.

Conclusion

Through the Peltier effect, thermoelectric cooler assemblies are used for refrigeration and temperature stabilization applications with heat loads up to 400 W. Thermoelectric cooler assemblies offer a more efficient, cost-effective, and reliable thermal control method when compared with alternative cooling technologies. Thermoelectric cooling is also the most environmentally friendly option because no hazardous refrigerants are used.

With the ability to heat and cool, thermoelectric cooler assemblies deliver precise temperature control — all in a smaller size unit. Due to their solid-state construction, thermoelectric cooler assemblies offer high reliability for years of service with little or no degradation in performance, reducing the total cost of ownership for the cooling solution.

Advertisement

Learn more about Electronic Products Magazine